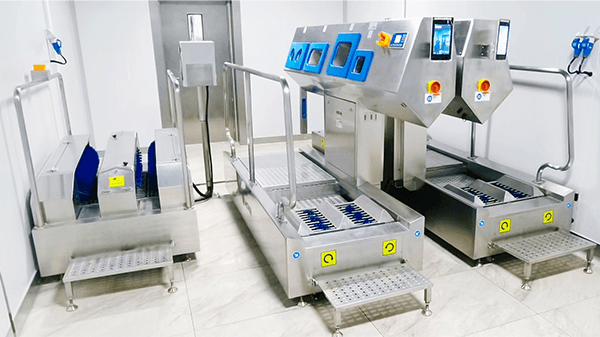

Automated Hygiene Station: Hands & Boot Sanitizing Made Easy

The Critical Role of Hygiene in Food Processing In the food industry, maintaining impeccable hygiene standards is non-negotiable. Contamination risks at entrances of workshops in the food factories can compromise food product safety, brand reputation, and regulatory compliance. This is where hygiene stations shine as essential food plant hygiene solutions. Designed to automate hand and […]

Automated Hygiene Station: Hands & Boot Sanitizing Made Easy Read More »