Introduction:Ensuring Food Safety and Regulatory Compliance in Poultry Facilities by Choosing the Right Hygiene Station Manufacturer

In poultry processing, selecting the right food factory hygiene station is essential to ensure food safety, prevent contamination, and comply with industry regulations. Choosing the correct hygiene station manufacturer is crucial for providing equipment that meets regulatory requirements, effectively controls pathogens, and enhances processing efficiency. As a result, having the right equipment in place is the foundation for safe and compliant food processing operations.

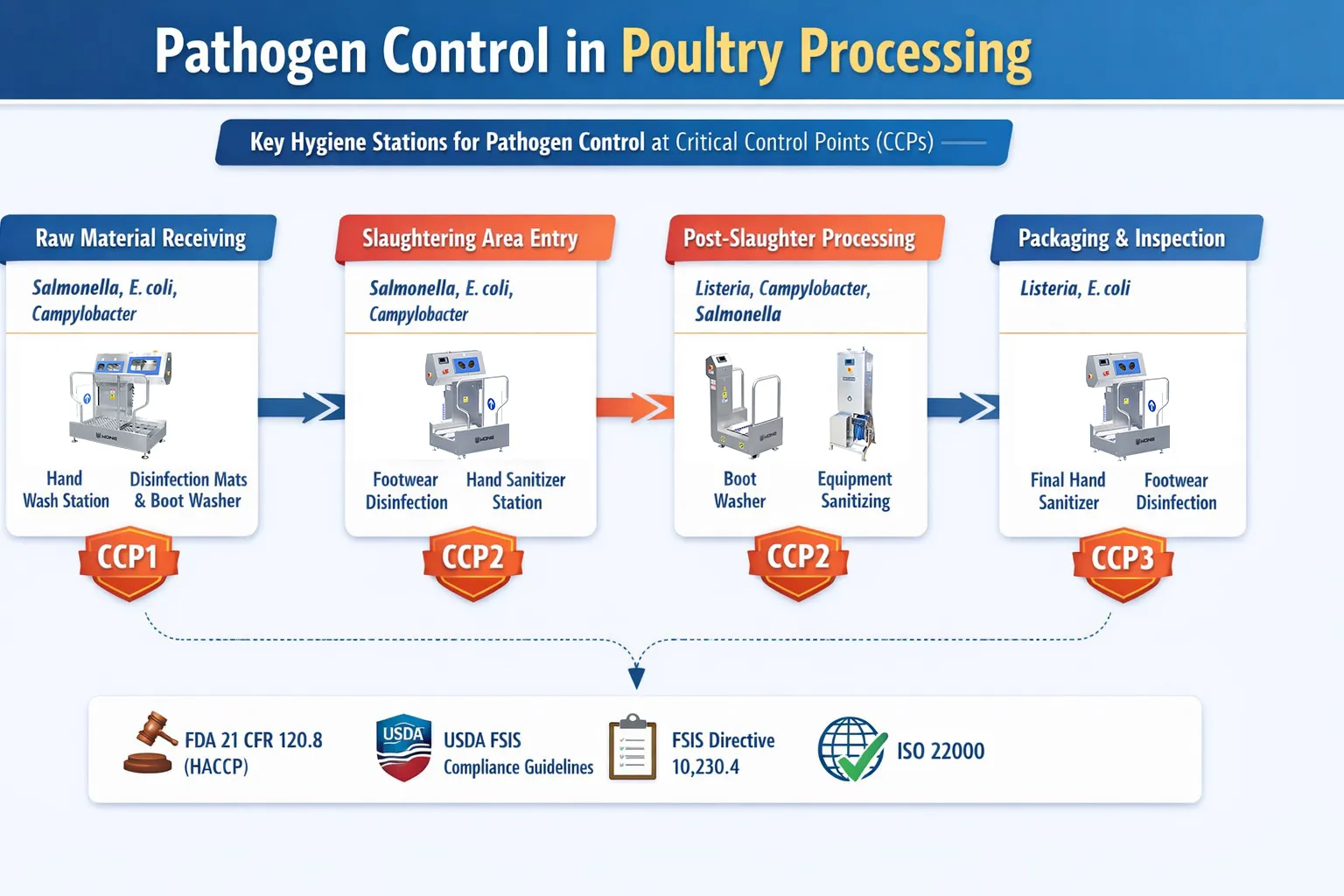

Understanding Critical Control Points (CCPs) in Poultry Processing

Critical Control Points (CCPs) are stages in poultry processing where contamination risks are highest. Therefore, these points must be closely monitored to ensure that pathogens, such as Salmonella, Campylobacter, E. coli, and Listeria, are effectively controlled. Partnering with a trusted hygiene station manufacturer ensures that the equipment used at each CCP adheres to hygiene standards and successfully mitigates pathogen risks. Additionally, it guarantees that proper sanitation measures are in place at every critical point.

Key CCPs and Recommended Hygiene Equipment Solutions

| Control Point (CCP) | Pathogens Controlled | Regulatory Reference | Recommended Hygiene Equipment |

|---|---|---|---|

| Raw Material Receiving | Salmonella, E. coli, Campylobacter | FDA 21 CFR 120.8 – HACCP regulations for pathogen control | Hand wash stations, footwear disinfection mats, boot washers |

| Slaughtering Area Entry | Salmonella, E. coli, Campylobacter | USDA FSIS Compliance Guidelines for pathogen control during slaughter | Footwear disinfection systems, automated hand sanitizing stations |

| Post-Slaughter Handling & Processing | Listeria, Campylobacter, Salmonella | FSIS Directive 10,230.4 – Pathogen control during post-slaughter and packaging | Boot washers, equipment sanitization systems |

| Packaging and Inspection Areas | Listeria, E. coli | FSIS Directive 10,230.4 – Prevent contamination in ready-to-eat products | Final hand sanitizing stations, footwear disinfection |

Furthermore, using equipment that addresses these specific needs ensures optimal pathogen control and regulatory compliance across the entire processing chain.

Regulatory Compliance and the Role of Hygiene Equipment

HACCP (Hazard Analysis Critical Control Point)

HACCP requires food processors to identify critical control points where contamination risks are highest. These CCPs must be closely monitored to prevent contamination by pathogens such as Salmonella and E. coli.

-

Example: Footwear disinfection systems at the receiving point help control Salmonella and prevent external contamination.

FSIS Compliance Guidelines (USDA)

The FSIS Compliance Guidelines for Meat and Poultry Slaughter outline specific requirements for pathogen control, including at critical points such as slaughter and post-slaughter handling.

-

Example: Campylobacter control is required at the slaughtering and post-slaughter stages. Footwear and hand sanitizing stations are crucial for managing the pathogen at these points.

FSIS Directive 10,230.4 and ISO 22000

This directive provides guidelines for controlling Listeria monocytogenes at critical points in the processing line, particularly in ready-to-eat products.

-

Example: Implementing equipment sanitizing stations and regular hygiene practices at post-slaughter and packaging points is essential to controlling Listeria.

ISO 22000 specifies the requirements for a food safety management system and integrates the principles of HACCP and GMP to ensure food safety throughout the supply chain.

-

Example: Hygiene stations that address E. coli and Listeria control at critical points ensure compliance with ISO 22000 standards.

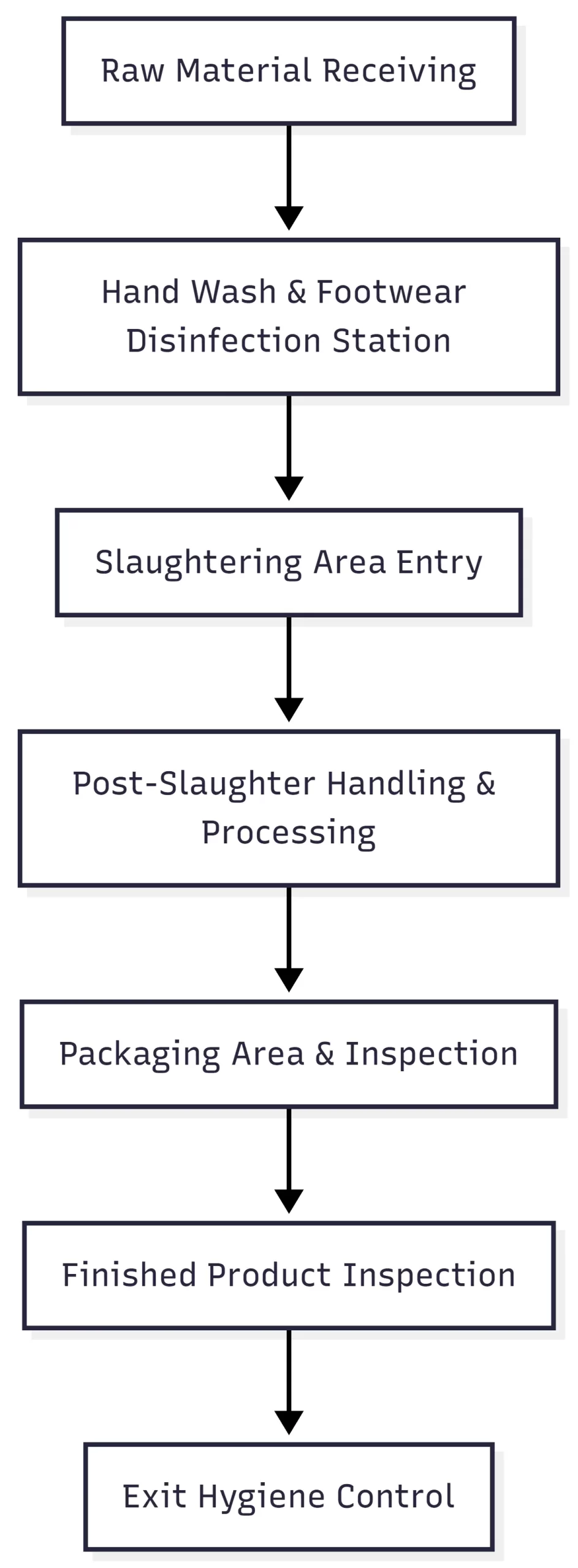

Poultry Processing Critical Control Points (CCPs) and Hygiene Equipment Flow

Emerging Best Practices in Hygiene Equipment Selection

While traditional methods such as hand washing and foot disinfection are fundamental, modern poultry processing facilities are increasingly integrating advanced solutions that focus on preventing contamination at a molecular level. Some of the emerging practices include:

UV-C Light Sanitization

Many poultry plants are incorporating UV-C light systems into their hygiene protocols, especially in areas where traditional disinfecting methods may have limitations. UV-C light can be used to disinfect surfaces, air, and even water in processing plants, offering an additional layer of pathogen control, particularly against Listeria and Salmonella.

Ozone Sanitization Systems

Ozone is becoming a preferred solution in poultry facilities for disinfecting water and air. Ozone sanitization systems can reduce pathogens in washing and cooling systems, minimizing cross-contamination risks during post-slaughter processing.

Real-Time Monitoring Systems

The integration of IoT (Internet of Things) and real-time monitoring systems in hygiene stations can provide continuous tracking of sanitation effectiveness. This can include temperature, humidity, and contamination sensors that alert facility managers to any deviations in hygiene standards, enabling immediate corrective actions.

Selecting the Right Hygiene Equipment for Your Facility

To effectively manage pathogens and comply with regulations, it’s important to choose the right hygiene equipment for each control point in the poultry processing line.

| Equipment | Function |

|---|---|

| Hand Wash Stations | Ensure proper hand hygiene, especially before entering critical processing zones. |

| Footwear Disinfection Systems | Prevent contamination from footwear, which can carry harmful pathogens into processing areas. |

| Automated Boot Washers | Provide thorough cleaning and disinfection of footwear before entry into slaughtering and processing areas. |

| Foot Sanitizing Mats | Placed at high-risk areas to ensure workers thoroughly clean their shoes before entering sensitive zones. |

Conclusion: Partnering with the Right Hygiene Station Manufacturer

The selection of an appropriate food factory hygiene station is critical to controlling pathogens like Salmonella, E. coli, Campylobacter, and Listeria in poultry processing. By adhering to HACCP, USDA FSIS guidelines, and ISO 22000, poultry facilities can ensure food safety, comply with regulations, and prevent contamination. Advanced hygiene solutions, such as UV-C sanitization and automated monitoring systems, are further enhancing pathogen control.

Partnering with a reputable food factory hygiene station manufacturer ensures that your poultry processing facility is equipped with cutting-edge technology to meet both current and future food safety standards.

Call to Action

To ensure your poultry processing facility meets industry regulations and effectively controls pathogens, explore Wone’s range of Hygiene Stations. Contact us today for a consultation on how we can help optimize your hygiene practices, improve food safety, and maintain regulatory compliance.