Maintaining high hygiene standards is critical for every food processing plant. As regulations become stricter, factories must ensure consistent hand hygiene, footwear sanitising, and controlled entry to prevent contamination. Choosing the right hygiene station for food processing plants not only improves food safety compliance but also enhances workflow efficiency.

This guide walks you through the key factors to consider when selecting a hygiene station, helping you find the most suitable system for your production environment.

1. Start by Identifying Your Hygiene Requirements

Before selecting equipment, evaluate the hygiene risks in your facility:

Number of workers passing through the hygiene area

Need for handwashing, hand disinfection, or both

Whether footwear cleaning is required (boot sole or full boot cleaning)

Required access control level

Available space for installation

2. Consider Automatic and Contactless Operation

Modern food factories prefer sensor-activated hygiene stations, because they:

Reduce manual errors

Prevent cross-contamination

Ensure every worker completes hygiene steps

Provide consistent sanitiser dosing

Improve traceability

Common automatic components include:

Touchless soap dispensers

Automatic hand sanitiser dosing

Auto-start boot sole brushes

Turnstile access control

This makes an automatic hygiene station with turnstile ideal for high-risk zones.

3. Choose Equipment That Meets Food Safety Standards

A high-quality hygiene station should be designed to support HACCP, IFS, BRC, and other food safety audit requirements. Look for:

Food-grade stainless steel (304/316)

Hygienic design without sharp corners

Easy-to-clean structure

Anti-splash and drainage system

Stable sanitiser concentration control

Using compliant equipment helps maintain strong audit results and prevents hygiene violations.

4. Select the Right Footwear Cleaning Type

Different factories require different shoe sanitising systems. Below is a comparison:

Hygiene Station Types Comparison

Type of Hygienic Equipment Best For Includes Advantages Boot Sole Cleaning Machine Standard food processing plants Rotating brushes, sanitiser dosing Fast foot cleaning, small footprint Full Boot Cleaning Station Meat, poultry, seafood plants Upper boot brushes, deep cleaning High-level hygiene, suitable for wet areas Walk-Through Disinfection Bath High-microbiology control areas Disinfection tank, sensors Strong disinfection, ideal for critical zones Hand & Boot Hygiene Combo Station Medium–large factories Handwashing + boot cleaning + turnstile Complete hygiene control, controlled entry

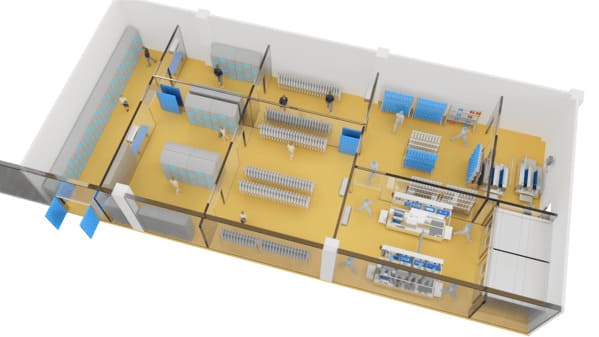

5. Plan According to Worker Flow and Space Layout

The hygiene station should match your factory layout:

Single-lane units for small teams

Dual-lane hygiene stations for medium factories

Full access control systems for high-traffic plants

Left/right orientation options

Enough queue space for peak production times

A well-planned layout prevents bottlenecks and keeps worker movement smooth.

6. Evaluate Maintainability and Long-Term Cost

Good hygiene equipment should offer:

Durable stainless steel construction

IP-rated electronics

Easy access for maintenance

Spare parts availability

Low sanitiser consumption

Instead of comparing only the purchase price, consider the total cost of ownership over 3–5 years.

7. Avoid Common Mistakes When Choosing a Hygiene Station

Factories often make these mistakes:

Choosing a station too small for worker flow

Ignoring footwear cleaning needs

Not considering access control

Buying equipment that’s difficult to clean

Choosing low-quality materials that rust in wet environments

Avoiding these issues helps maintain long-term compliance and hygiene performance.

8. Why a Good Hygiene Station Improves Food Safety

A well-designed hygiene entry system helps:

Reduce cross-contamination

Improve worker hygiene habits

Standardize hygiene procedures

Pass food safety audits more easily

Reduce product contamination risks

Enhance brand reputation

This is why hygiene stations are becoming standard equipment in modern food plants.

Conclusion

Selecting the right hygiene station for food processing plants involves evaluating hygiene risks, understanding food safety compliance requirements, comparing system types, and assessing worker flow. A properly selected system helps ensure worker safety, reduces contamination risks, and supports strong audit performance.

For factories looking to improve hygiene control, you can explore our related equipment such as the

Hand & Boot Hygiene Stations and

Boot Sole Cleaning Machines

to better understand the options available for different production environments.If you need a customised hygiene station recommendation based on your plant layout, production scale, or industry type, our team can provide guidance tailored to your needs.

To learn more about international hygiene standards, you may also refer to:HACCP International – https://www.haccp-international.com/

BRCGS Food Safety Standard – https://www.brcgs.com/

USDA Food Safety & Inspection Service (FSIS) – https://www.fsis.usda.gov/

European Commission Food Safety – https://food.ec.europa.eu

These authoritative resources help ensure your hygiene station selection aligns with global food safety expectations.

FAQ

1. What is a hygiene station in food processing?

A hygiene station is an automated system designed to ensure workers clean and disinfect their hands and shoes before entering production areas.

2. Do all food factories need boot sole cleaning?

Not all factories require it, but most benefit from boot sole cleaning machines, especially wet or raw processing areas.

3. What features should a hygiene station include?

Contactless operation, automatic dosing, stainless steel design, easy maintenance, and access control are essential.

4. How much space is needed for a hygiene station?

Small units may require only 1–1.5 meters, while full systems with turnstiles may require 3–5 meters depending on worker flow.

5. Are hygiene stations required for food safety audits?

While not always mandatory, they significantly support HACCP, IFS, and BRC compliance and reduce audit risks.

6. Can hygiene stations reduce cross-contamination?

Yes. They standardize hygiene steps and ensure workers complete them before entering production zones.