In a food factory, the line between a safe product and a recall threat is often traced back to the floor. Footwear is a primary vector for cross-contamination, tracking pathogens from raw material areas to processing lines, from packaging halls to high-care zones. A single pass through a contaminated corridor can undermine your entire food safety protocol.

Traditional boot scrubbers are a step in the right direction, but they lack intelligence, consistency, and often, thoroughness. It’s time for a smarter solution.

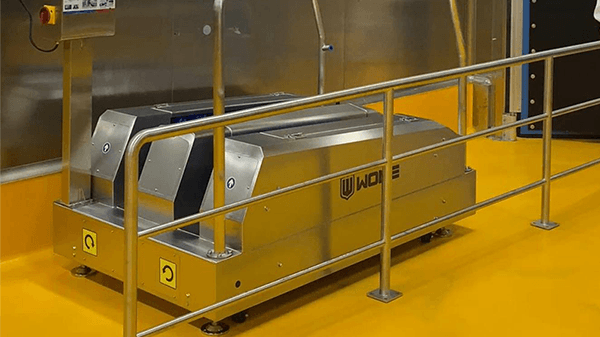

Introducing the next generation of entryway hygiene: The Two-Way Smart Boot Washer. Designed for the modern food facility, this system doesn’t just clean boots—it guarantees it, with automated, data-driven precision at every critical doorway.

The Dual Threat: Why Two-Way Cleaning is Non-Negotiable

Most boot washers are designed only for entry into a clean area. But what about exit? Boots leaving a high-risk area can carry contaminants out, spreading them to locker rooms, cafeterias, and other transition zones, creating a cycle of contamination.

Our two-way boot cleaning machine is engineered for this exact scenario. Installed at any doorway, it provides a powerful, automated cleaning cycle:

Upon Entry: Removes dirt, debris, and external contaminants before an employee steps into a clean workshop.

Upon Exit: Washes away organic matter, allergens, and biofilms produced within the room itself, preventing their spread to other areas.

This two-way action creates a true hygiene barrier, containing contamination and significantly elevating your facility’s overall sanitary status.

Intelligent Cleaning: The i-Clean System Advantage

What truly sets this boot washer apart is its brain. The integrated i-Clean System transforms a mundane task into a precise, controllable, and auditable sanitation event.

Adjustable Cleaning Time: Program the exact wash duration needed for different zones. A high-care entry might require a longer, more rigorous cycle than a packaging area.

Precise Chemical Dosing: Eliminate waste and ensure efficacy. The system automatically dispenses a perfect, consistent dose of detergent or sanitizer every time, removing human error from the equation.

Auto Chemical Concentration Monitoring: The system doesn’t just dose; it ensures the solution is always at the correct potency for optimal cleaning and sanitizing, alerting you if a tank needs replenishing.

This smart technology means you don’t just hope boots are clean—you have the data and consistency to know they are.

Key Benefits for Your Food Production Facility

Investing in a smart boot scrubber delivers measurable returns in safety, compliance, and operations.

Superior Pathogen Control: Dramatically reduces the risk of cross-contamination from Listeria, E. coli, Salmonella, and allergens, protecting your product and your consumers.

Unmatched HACCP & SQF/BRC Compliance: Provides verifiable, consistent cleaning records. The programmable settings are perfect for validating your SSOPs (Sanitation Standard Operating Procedures) during audits.

Reduced Labor & Chemical Costs: Automation frees up valuable employee time. Precise chemical dosing prevents waste and ensures you’re not using more detergent than necessary.

Enhanced Workplace Safety: Thoroughly cleaned boots improve floor traction, reducing slip-and-fall hazards in wet environments.

Water Efficiency: The closed-system design recirculates water and solution, using significantly less water than a hose-down station.

Ideal for Critical Control Points

This system is the ultimate guardian for any doorway, including:

Entrances to the main production and processing floors

Transition points into Ready-to-Eat (RTE) or high-care areas

Entryways to packaging and storage zones

Pass-throughs between raw and cooked product areas

Engineered for the Demands of Food Manufacturing

Built to perform in the toughest environments, our boot washer features:

Durable, Chemical-Resistant Construction: Withstands frequent use and harsh sanitation chemicals.

Effective 360° Cleaning: Rotating brushes and targeted jets clean soles, sides, and the back of boots thoroughly.

Easy Maintenance: Designed for quick and easy cleaning and service to fit into your existing sanitation schedule.

Stop the Spread at the Door

Don’t let your footwear hygiene be an afterthought. In the era of smart manufacturing, every component of your facility should be optimized for safety and efficiency.

Ready to build a smarter hygiene barrier? Contact us today to learn more about our Two-Way Tech boot washers and request a custom quote for your facility.