Foodborne illnesses cost the global economy billions annually, often originating from inadequate hand hygiene in food handling environments. Traditional handwashing methods suffer from inconsistent compliance, cross-contamination risks, and untracked hygiene practices. The next-generation automated hand wash station integrates five critical functions—wetting, soaping, washing, drying, and disinfecting—into a single touchless workflow, leveraging sensor technology to eliminate human error and set new standards in food safety protocols.

The Critical Need for Automated Hand Hygiene

Food processing facilities and commercial kitchens face persistent hygiene challenges:

Inconsistent compliance: Studies reveal workers skip or improperly execute hand hygiene 50-95% of the time on occasions requiring it.

Training deficiencies: 67% of workers receive insufficient hand hygiene training according to food safety audits

Cross-contamination risks: Contaminated faucet handles spread pathogens to 44% of workers, according to microbial studies

Resource waste: Conventional handwashing consumes 1-2 gallons per use versus 0.04 gallons in closed-loop systems

Automated 5-step stations address these gaps through engineering controls that enforce protocol compliance while capturing verification data for food safety audits.

Inside the 5-Step Automated Process

Step 1: Wetting hands

When your hands are close to the faucet, the advanced infrared sensor detects your hands under the device without physical contact, triggering a precise temperature-controlled water spray on your hands.

Step 2: Getting soap

Proximity sensors activate food-grade antibacterial soap dispensers, delivering a pre-measured cleaning chemical, optimized for maximum pathogen removal. The viscous formula clings to skin surfaces without dripping, containing dermal protectants to prevent irritation during frequent washes. Units can store up to 2L, and with low-level alerts for maintenance staff.

Step 3: Wash hands

After rubbing, cleaning hands witha cleaning chemical, flushing hands.

Step 4: Drying hands

After rinsing, immediately air dry your hands to remove 99.97% of moisture in 10-15 seconds. Laminar airflow forces contaminants downward, while the heating element destroys microbial structures.

Step 5: Sanitizing and chemical disinfecting hands

Spraying hands with a food factory disinfectant is sufficient to inactivate 99.9% of norovirus, E. coli, and Salmonella.

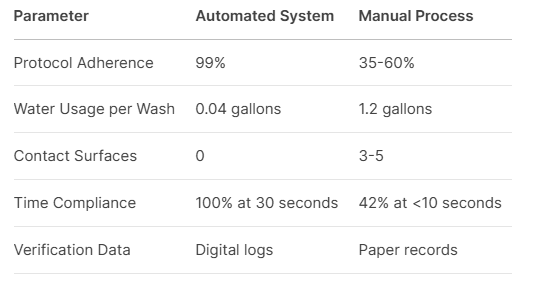

Automated vs. Manual Handwashing Compliance Metrics:

Smart Technology Integration

Beyond the hygiene process, IoT-enabled stations transform compliance monitoring:

Biometric authentication: Facial recognition links handwash events to individual employees for accountability

Real-time analytics: Cloud-connected sensors track usage rates, soap consumption, and filter statuses, predicting maintenance needs before failures occur

Compliance alerts: Integrated displays flash reminders when workers approach production areas without recent washes

Operational Advantages for Food Facilities

Risk Mitigation

Automated stations reduce cross-contamination by eliminating high-touch surfaces per wash event. The closed-loop system prevents splashback contamination—a critical vulnerability in raw meat handling areas. UV-C deactivation provides final pathogen elimination where soaps and friction may fail.

Resource Optimization

Facilities report 45-60% reductions in water/sewer costs and 38% lower soap expenditures through precision dosing. Maintenance hours decrease by 75% with centralized monitoring replacing manual checks. The compact footprint (106cm height × 70cm diameter) allows retrofitting into existing layouts without reconstruction 37.

Compliance Assurance

Digital verification logs provide defensible audit trails showing:

Individual employee wash frequency and duration

Real-time compliance rates across shifts

Maintenance records for regulatory inspections

Customizable reports for FDA, HACCP, or ISO 22000 requirements

Facilities demonstrate 86% higher compliance ratings within 60 days of implementation.

Implementation Considerations

When deploying automated stations:

Workflow Integration: Position units at zone transition points (e.g., entry to processing workshop, packaging areas) with sufficient queuing space

Connectivity: Ensure robust WiFi coverage for IoT functions or opt for local data storage with daily uploads

ROI and Sustainability Impact

Food processing facilities typically achieve 14-month payback periods through:

62% reduction in water costs versus conventional stations

80% lower paper towel expenses

47% decrease in audit non-conformities

23% reduction in absenteeism from hygiene-related illnesses

Elevate your food safety standards with WONE’s fully automated hand wash station—where engineering precision meets uncompromising hygiene. Our 5-step system transforms regulatory compliance from a documentation challenge to an automated assurance.

Contact our hygiene solutions team today to schedule your facility assessment and pilot program.