The Complete Guide to Managing Work Boots in a Food Factory After Work

In the world of food production, hygiene is paramount. While protocols for hand washing and protective clothing are strictly enforced, work boot management is a critical frontline defense against cross-contamination that is often overlooked. Mud, moisture, and microbes on boots can jeopardize product safety and facility compliance.

A proper post-shift routine is non-negotiable. This guide breaks down the essential steps of cleaning, drying, disinfection, and placement, and introduces how modern technology can streamline this process to unparalleled levels of efficacy and efficiency.

Step 1: The Essential Clean – Removing Visible Contaminants

Before any disinfection can occur, all visible soil must be completely removed. Debris can shield microorganisms, rendering disinfectants useless.

Action: Use a dedicated boot scraper and stiff brush to remove large particles. Then, scrub boots thoroughly with a food-safe detergent and a brush, paying close attention to the deep treads of the sole. A final rinse with low-pressure water will wash away all loosened grime and soap residue.

Pro Tip: Perform this initial clean at a designated station immediately after exiting the production area to prevent tracking contaminants further.

Step 2: The Revolution in Drying: Why Warm Air is a Game-Changer

Damp, dark boot interiors are a breeding ground for bacteria, mold, and unpleasant odors. Traditional air-drying is slow and often ineffective, especially in humid environments.

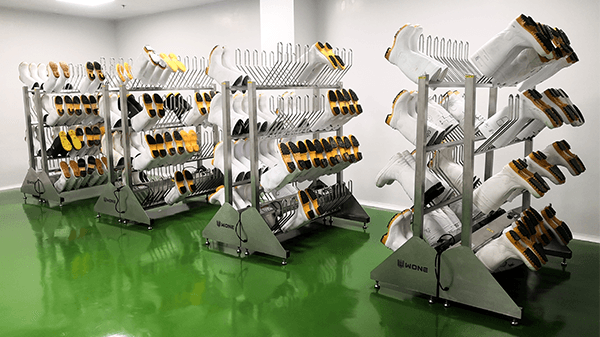

This is where a specialized boot drying rack with a gentle warm air function becomes indispensable. Simply placing your cleaned boots on the rack activates a cycle of circulated warm air that rapidly evaporates moisture from both the exterior and the hard-to-reach interior lining.

Benefit: This method is far superior to air drying. It ensures boots are completely dry before the next shift, eliminating the moisture that pathogens need to thrive. It also preserves the integrity of the boot materials by avoiding the damaging high heat of radiators or direct heaters.

Step 3: Powerful Disinfection: Harnessing the Power of Ozone

After cleaning and drying, the next critical step is disinfection—killing the invisible pathogens that remain. Modern technology offers a powerful, hands-free solution.

Advanced boot drying racks are equipped with an ozone (O³) function. Ozone is a highly effective oxidizing agent that is used to destroy bacteria, viruses, and odors at their source.

How it Works: After placing your cleaned boots on the rack, you can activate the ozone disinfection cycle. The ozone gas permeates every fold, stitch, and pore of the boot material, ensuring comprehensive coverage that sprays and wipes can miss.

Benefit: This provides a deep, chemical-free, and automated disinfection process. It effectively neutralizes harmful microorganisms and eliminates persistent odors, ensuring your boots are not just visually clean but microbiologically sanitized.

Step 4: Secure and Sanitary Placement

The final step is proper storage. After the integrated drying and ozone disinfection cycle is complete, your boots are already in the ideal storage location.

A Dedicated Space: A boot drying rack serves as an organized, ventilated storage unit. Keeping boots elevated and separate prevents them from touching each other or the floor, avoiding re-contamination.

Conclusion: Integrating Technology for Uncompromising Safety

Managing work boots is a critical control point in your facility’s food safety plan. By adopting a rigorous routine of Cleaning, Drying, and Disinfecting, you significantly reduce the risk of cross-contamination.

The process is revolutionized by investing in a dedicated boot drying rack with warm air and ozone functions. This all-in-one solution ensures:

Rapid, thorough drying that protects your investment in footwear.

Powerful, automated disinfection that reaches where manual methods can’t.

Organized, hygienic storage that maintains readiness for the next shift.

Upgrade your post-work protocol with technology designed for the highest standards of food safety.

FAQ Section

Q: How does ozone disinfection compare to a chemical boot bath?

A: Ozone is a gas that penetrates materials more completely than liquid solutions, ensuring no spots are missed. It’s also a dry process, meaning no chemical residue is left behind, and it eliminates the need to mix, manage, and dispose of chemical solutions daily.

Q: Is the warm air setting safe for all types of work boots?

A: Yes. Our rack uses a low-temperature, gentle warm air designed to dry boots effectively without using the extreme heat that can crack leather or degrade rubber and adhesives over time.

Q: How long does the full dry and disinfect cycle take?

A: Cycle times vary by model, but most of our racks can complete a full dry and ozone disinfection cycle overnight, ensuring your boots are ready, safe, and comfortable for your next shift.

Q: Can I use this rack if my boots are extremely muddy?

A: No. The first step of physical cleaning (scraping, brushing, and rinsing) is always essential. The rack is designed for the post-cleaning phase to provide deep drying and disinfection. Placing muddy boots inside will soil the unit and reduce its effectiveness.