Poultry processing plants face significant challenges in ensuring food safety, controlling contamination risks, and meeting regulatory standards. Hygiene technologies, including foam cleaning machines, are critical tools in achieving these goals. This blog delves into the role of foam cleaning machines in poultry processing, offering a detailed exploration of how they address Critical Control Points (CCPs), mitigate bacterial risks, and comply with industry regulations. We will also provide actionable steps, equipment introductions, regulatory references, and real-world case studies to offer a comprehensive understanding of the hygiene technologies used in poultry processing.

1. Critical Control Points (CCPs) and Contamination Risks in Poultry Processing

Critical Control Points (CCPs) are stages in the poultry processing process where contamination risks are most likely to occur. The identification and management of these points are essential for preventing foodborne illnesses. Below is a breakdown of key CCPs and the associated bacteria that pose risks:

| CCP Stage | Contamination Risk | Common Bacteria | Control Measures |

|---|---|---|---|

| Receiving and Inspection | Raw materials may carry pathogens from farms. | Salmonella, Campylobacter | Inspect and reject contaminated raw materials. |

| Slaughter and Dressing | Bacterial contamination from animal surfaces. | Salmonella, Escherichia coli | Implement hygiene protocols, use antimicrobial sprays. |

| Chill Tank | Inadequate chilling may promote bacterial growth. | Listeria monocytogenes | Ensure correct chilling times and temperatures. |

| Packaging | Cross-contamination from processing lines to packaging. | Salmonella, Listeria | Clean and disinfect packaging lines regularly. |

2. The Role of Foam Cleaning Machines in Poultry Processing

Foam cleaning machines are indispensable in addressing hygiene challenges at critical control points. They offer superior cleaning efficiency by using specially formulated cleaning agents that adhere to surfaces in the form of foam, providing extended contact time for microbial elimination. Here’s how they help at each stage of poultry processing:

Slaughter and Dressing: Foam cleaning systems can disinfect slaughtering tools, conveyors, and processing areas where pathogens like Salmonella and Campylobacter are prevalent.

Post-Slaughter: In this stage, foam cleaners effectively remove organic residues, preventing bacterial growth on surfaces like carcass holders and processing tanks.

Pre-Packaging and Packaging Areas: The use of foam cleaning machines ensures that packaging areas are sanitized, reducing the risk of cross-contamination before products are sent to market.

3. Addressing CCPs with Foam Cleaning Technology

The introduction of foam cleaning machines allows poultry processing plants to meet industry hygiene standards and address CCPs effectively. Here is how foam cleaning systems help control these critical points:

Receiving and Inspection: Implementing foam cleaning protocols at this stage ensures that any bacterial contamination on equipment or containers is removed before raw materials are processed.

Slaughter and Dressing: During slaughter, foam cleaning machines disinfect all equipment used in the process, reducing microbial contamination risks from the surface of poultry.

Post-Slaughter: Foam cleaners are ideal for removing blood, fecal matter, and other contaminants, minimizing bacterial growth and preventing cross-contamination in subsequent stages.

Equipment Introduction: Foam Cleaning System for Poultry Processing

The Foam Cleaning System (Model 325E) is a high-efficiency foam cleaner designed specifically for poultry processing plants. The system uses powerful foam jets to clean large surfaces, including processing lines, chill tanks, and packaging areas, ensuring optimal sanitation without wasting chemicals.

For more details or to purchase the Foam Cleaning System (Model 325E), visit [Product Link].

4. Industry Pain Points and Solutions

Despite the presence of advanced cleaning technologies, poultry processors face several challenges that can hinder food safety. These include:

Inconsistent Cleaning Results: Manual cleaning methods can lead to inconsistent results, which could leave harmful bacteria behind.

High Chemical Consumption: Excessive use of cleaning agents increases operational costs and environmental impact.

Time-Consuming Processes: Traditional cleaning takes longer, leading to decreased processing efficiency and increased downtime.

Solutions:

Automated Foam Cleaning Systems: By automating the foam cleaning process, poultry plants can achieve consistent cleaning results and reduce manual labor.

Eco-Friendly Chemical Solutions: Foam cleaning machines can be used with environmentally friendly chemicals, reducing the environmental footprint of the cleaning process.

Reduced Cleaning Time: Foam cleaning machines provide quicker cleaning cycles, improving operational efficiency and minimizing downtime.

5. Regulatory Framework and Compliance

Regulatory compliance is crucial in poultry processing. Below are some of the key regulations that poultry plants must adhere to, along with how foam cleaning machines help ensure compliance:

HACCP (Hazard Analysis and Critical Control Points): According to the FDA Food Code 2009 (Section 1-112), poultry processors must implement CCPs at critical stages to prevent contamination. Foam cleaning systems help meet these requirements by effectively cleaning at each CCP, particularly in slaughter, chill tanks, and packaging areas.

ISO 22000:2018 (Food Safety Management Systems): ISO 22000:2018 mandates that poultry processors ensure effective sanitation. Foam cleaning machines are an essential tool for achieving compliance by controlling microbial contamination at every stage of processing. You can learn more about ISO 22000 from ISO’s official website.

GMP (Good Manufacturing Practices): Under 21 CFR 110.35, GMP requires that processing equipment be maintained in a sanitary condition. Foam cleaning systems ensure that all equipment meets these standards and reduces the risk of contamination. Further details about GMP regulations can be found on the FDA’s website.

6. Industry Case Study: Successful Implementation of Foam Cleaning Machines in Poultry Processing

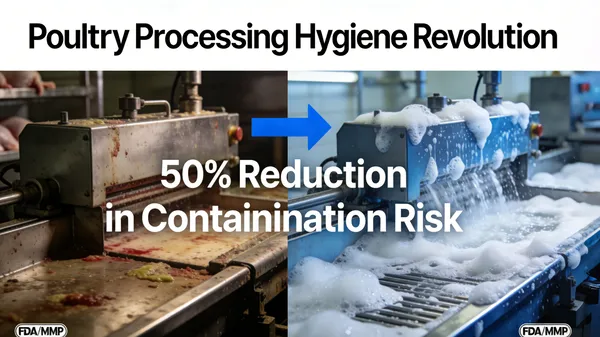

Case Study: XYZ Poultry Processing Plant (USA)

XYZ Poultry Processing Plant, a major poultry supplier in the U.S., faced significant hygiene challenges in its processing lines. The company struggled with contamination control during the slaughter and dressing stages, leading to higher bacterial counts on poultry carcasses. After implementing a Foam Cleaning System (Model 325E), the plant saw:

A 50% reduction in bacterial contamination at the slaughter stage.

An improvement in HACCP compliance due to better sanitation protocols.

A 30% decrease in cleaning time, allowing the plant to increase overall productivity.

By investing in foam cleaning technology, XYZ Poultry Processing Plant not only achieved higher hygiene standards but also improved efficiency and regulatory compliance.

7. Conclusion and Recommendations

Poultry processing plants must prioritize hygiene and food safety to prevent contamination and meet regulatory requirements. Foam cleaning machines are an essential part of this effort, as they help control Critical Control Points (CCPs), improve cleaning efficiency, and ensure compliance with industry regulations such as HACCP, ISO 22000, and GMP.

By implementing these technologies and following best practices for cleaning and sanitation, poultry processors can enhance food safety, minimize risks, and improve operational efficiency. We encourage all poultry processing plants to explore the benefits of foam cleaning machines and take action to modernize their cleaning protocols.

For more information on how foam cleaning systems can transform your poultry processing operation, contact us or explore our Foam Cleaning Machine Solutions.

References:

FDA Food Code 2009: Section 1-112

ISO 22000:2018 Food Safety Management Systems

21 CFR 110.35 – GMP for Food Processing