Introduction

Dairy hygiene management is a critical aspect of dairy production, focusing on preventing cross-contamination and ensuring product safety. In the dairy industry, proper hygiene controls can prevent microbial risks, maintaining high standards for quality and safety.

Critical Control Points (CCP) in Dairy Production

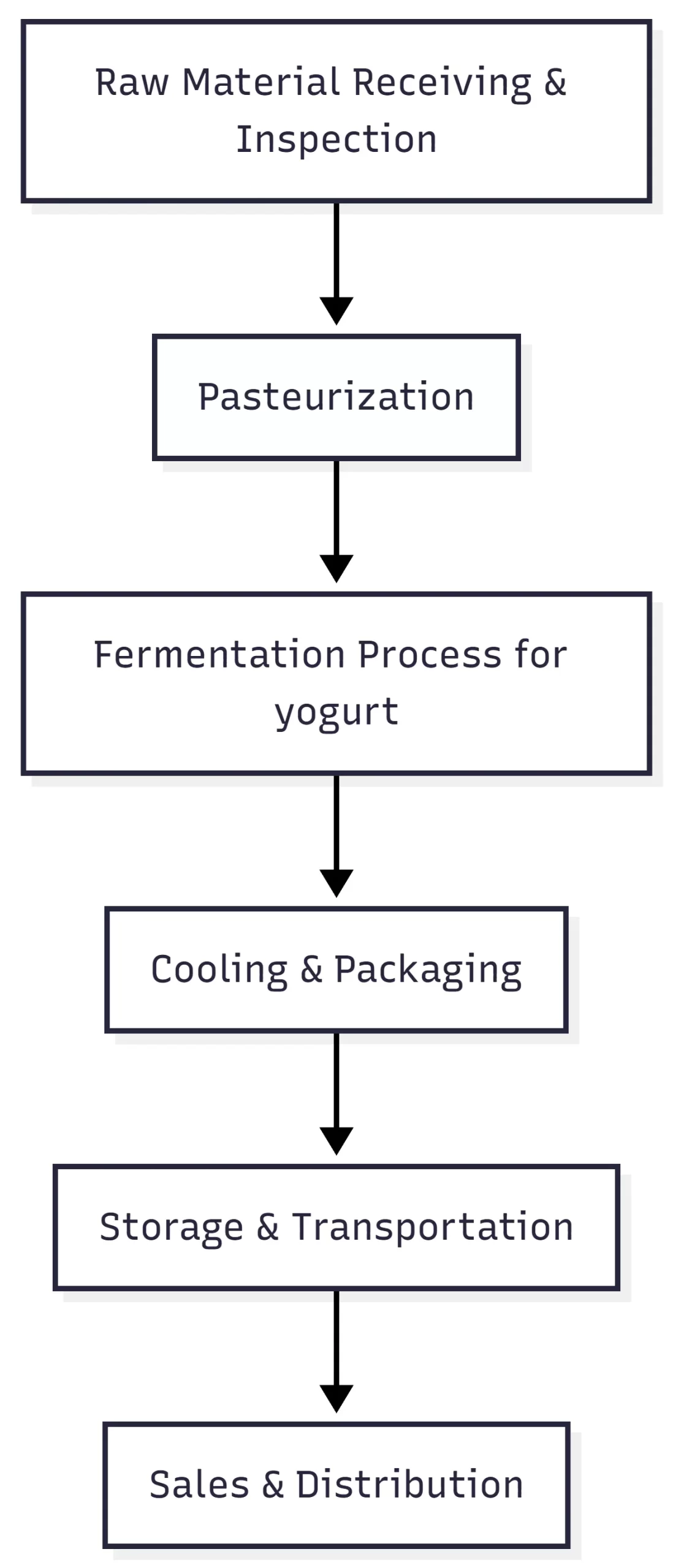

In dairy production, CCP (Critical Control Points) refers to stages in the production process that must be controlled and monitored to ensure the safety of the final product. Below are the key critical control points in dairy production:

| Process Step | Critical Control Point (CCP) | Control Measures | Monitoring Methods |

|---|---|---|---|

| Raw Material Receiving & Inspection | Initial raw material (milk) quality and safety checks | Monitor for pathogenic microorganisms or chemical contaminants | Microbiological testing, antibiotic testing, quality control acceptance standards |

| Pasteurization | Temperature and time control during heating | Control temperature and processing time to kill bacteria and pathogens | Automatic temperature control systems, real-time temperature recording, regular calibration of equipment |

| Fermentation Process | Control of fermentation temperature, humidity, and time | Control environmental conditions during fermentation to avoid contamination | Temperature and pH monitoring, fermentation process logs, automatic alarm systems |

| Packaging | Contamination control in packaging areas | Strict sterilization and hygiene management to prevent external contamination | Regular cleaning and sanitization, microbiological testing, air quality monitoring in packaging areas |

| Cold Chain Logistics & Distribution | Temperature control during transportation | Ensure temperature does not exceed safety standards during transport to prevent microbial growth | Cold chain logistics equipment with temperature control and real-time monitoring, temperature data logging and alarm systems |

Dairy Production Process Flow Diagram:

News Background:

According to an article published by Food Safety Magazine, a well-known dairy company recently faced a bacterial contamination issue in a batch of yogurt. This contamination was linked to the company’s failure to properly manage its pasteurization and fermentation processes. The incident attracted global media attention and forced the company to recall its products, facing millions of dollars in fines. The root cause of the problem was the poor design of the production facilities, which led to inadequate hygiene control and sanitization during production.

Case Analysis:

-

Identifying the Issues:

-

Poor Facility Design: In the company’s production facility, certain critical areas (such as fermentation tanks and packaging zones) were designed with hygiene dead zones that were difficult to clean and sanitize properly. Specifically, the layout of the fermentation process allowed microorganisms to proliferate between equipment.

-

Inadequate Hygiene Management: The hygiene operations were not systematically standardized, and employees were not strictly following sanitation procedures during production. This led to ineffective cleaning and sanitization.

-

Cold Chain Failure: The company’s cold chain system failed during transportation, causing temperature fluctuations that allowed pathogenic microorganisms to grow, exacerbating cross-contamination.

-

-

Solution and Improvement Measures:

a. Redesigning and Optimizing Production Facilities:

The company overhauled its production facility. It redesigned fermentation and packaging areas to ensure that all critical zones could be properly cleaned and sanitized. Additionally, they introduced automated cleaning systems that could perform sanitation in real-time during production, reducing human error.b. Strengthening the Hygiene Management System:

The company implemented a more rigorous hygiene management system, improving employee training and the execution of operational protocols. For example, at the pasteurization and packaging stages, they added microbiological monitoring systems and leveraged technology to ensure temperature control and sanitation protocols were correctly followed.c. Upgrading the Cold Chain Logistics System:

To prevent temperature fluctuations during transportation, the company upgraded its cold chain logistics system. All transportation vehicles were fitted with temperature monitoring devices, and the company tracked temperature data throughout the journey. If the temperature deviated from the safe range, the system would trigger an immediate alarm and corrective actions would be taken.d. Regular Risk Assessments and Audits:

To prevent similar incidents in the future, the company began conducting regular risk assessments and invited third-party organizations to perform food safety audits and certifications, ensuring all production stages met international food safety standards (e.g., ISO, HACCP certification).

Dairy hygiene management is crucial in all stages of dairy production, from raw material inspection to packaging.

Key Takeaways from the Case:

-

Importance of Facility Design and Cleaning Systems:

Production facilities should comply with Good Manufacturing Practices (GMP) standards to avoid dead zones and contamination sources, especially in areas where food comes into direct contact with equipment, such as fermentation and packaging. The introduction of automated cleaning systems can greatly enhance the efficiency and accuracy of sanitation, reducing human error. -

Strengthening Employee Training and Operational Protocols:

Hygiene management is not just about equipment and technology; it also requires enhancing employees’ awareness and adherence to sanitary standards. Companies should regularly train employees, especially in critical processes like pasteurization and packaging, to follow strict hygiene protocols. -

Cold Chain Management is Crucial:

During transportation, cold chain management is essential to ensure product quality and safety. Companies should rigorously monitor the cold chain system to maintain constant temperatures and address any temperature deviations promptly. -

Ongoing Risk Assessment and Continuous Improvement:

Dairy companies should establish continuous risk assessments and improvement mechanisms, regularly reviewing potential risks in production processes and making adjustments according to the latest safety standards. Third-party audits can help identify issues early and guide improvements.

Effective dairy hygiene management ensures that products meet safety standards and avoid microbial contamination.

External Links:

These platforms provide valuable news, standards, and technical documents to help dairy producers stay up to date on the latest food safety regulations and technological advancements, further enhancing their food safety management systems.

Conclusion:

By analyzing CCP (Critical Control Points) in dairy production and delving into a real-world case study, we can see that dairy production faces significant challenges in preventing cross-contamination and ensuring food safety. However, by optimizing facility design, strengthening hygiene management practices, improving cold chain logistics, and conducting regular risk assessments, dairy producers can significantly reduce food safety incidents, improve production efficiency, and meet global food safety standards.