Handwashing Station in Food Plant: Introduction to Proper Hand Hygiene

A proper handwashing station in a food plant is essential for preventing microbial contamination and ensuring food safety Workers’ hands are among the primary sources of microbial contamination and cross-contamination. Therefore, implementing standardized, monitored, and effective handwashing and hand disinfection procedures is essential for food plants aiming for high standards and compliance with food safety regulations. This guide follows the WHO handwashing guidelines and the HACCP framework to provide actionable guidance for food processing facilities, including a real-world, data-driven case study.

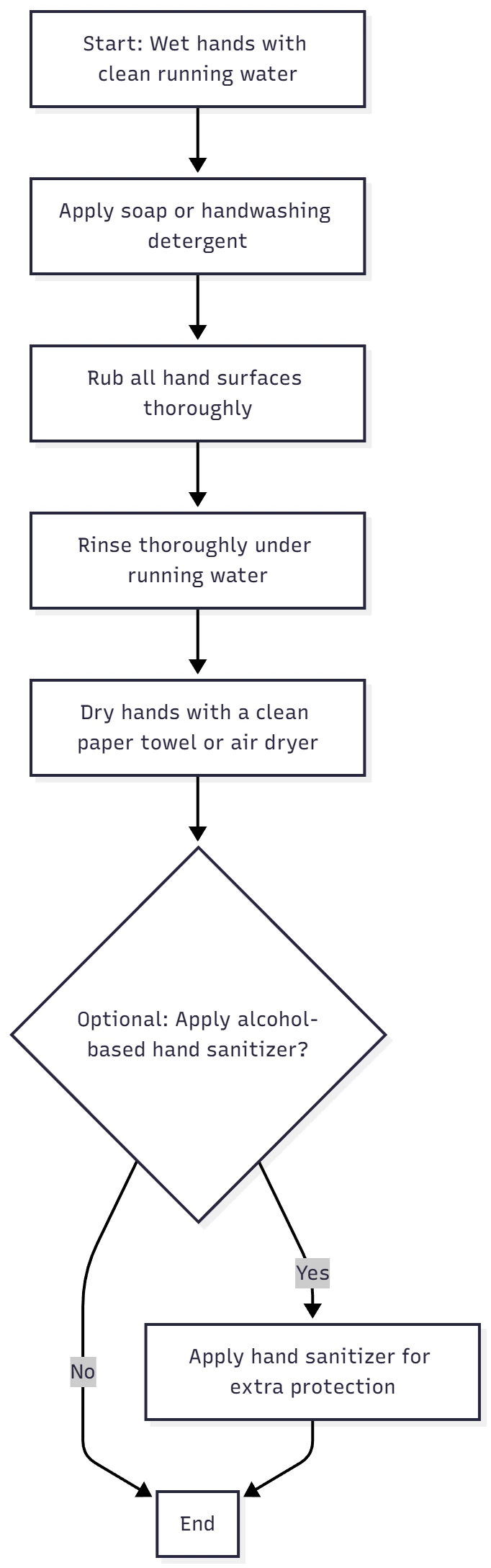

Correct Handwashing Procedure for a Food Plant Handwashing Station

Manual handwashing stations (traditional sinks, faucets, soap, and paper towels/air dryers) are low-cost and flexible but depend heavily on employee compliance.

Automated handwashing or sanitizing systems (sensor-based soap dispensers, automated sinks, or integrated hand disinfection units) reduce touchpoints, improve compliance, and provide better monitoring but require higher initial investment and maintenance.

“For more details on automated hygiene solutions, check our food plant handwashing equipment page.”

Comparison:

Manual: flexible, low-cost, reliant on employee behavior.

Automated: consistent dosing, touchless, easier to monitor, but higher cost and maintenance requirements.

Manual vs Automated Handwashing Stations in Food Plants

Observations from multiple food processing facilities reveal the following issues:

Employees sometimes skip handwashing at critical moments such as entering production areas or after handling waste. (ScienceDirect)

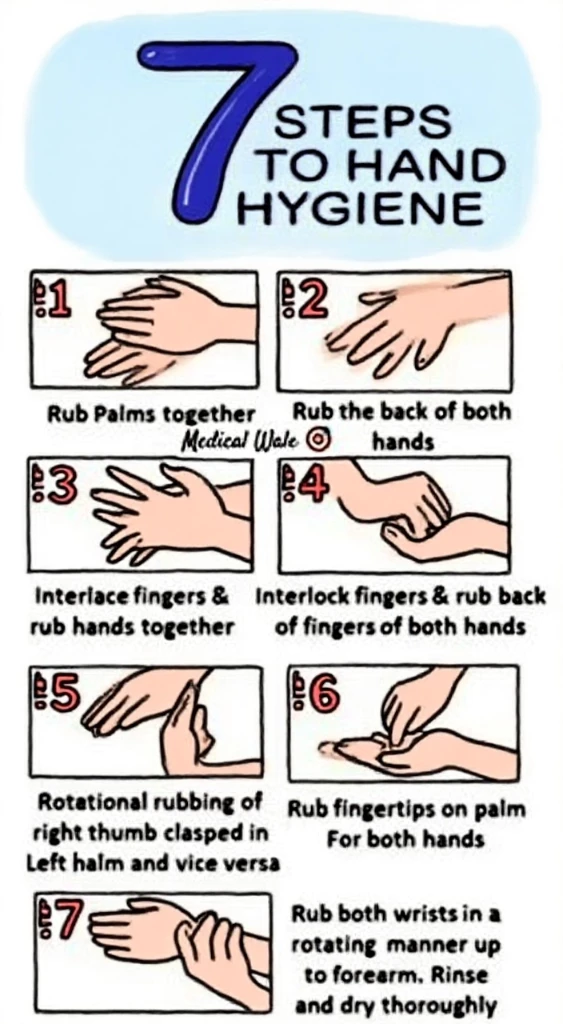

Handwashing duration is often insufficient (<20 seconds), and certain areas (fingernails, thumbs, between fingers) are frequently missed. (PubMed)

After washing, hand sanitizers are rarely applied, especially when moving between high-risk areas.

Lack of monitoring or supervision leads to inconsistent compliance across shifts and employees.

Even with proper facilities, non-compliance significantly increases the risk of microbial contamination and cross-contamination.

Real-World Case Study: Handwashing Station Compliance in a Food Plant

Study: Observation of Food Handlers’ Hand Hygiene Behavior During Production at a Sandwich-Making Factory (2024, Journal of Food Protection)

(link)

Key Data:

588 critical hand hygiene opportunities observed; 32% were completely missed.

Only 1% of handwashing events fully complied with the facility’s standard operating procedures.

95% of handwashing attempts lasted less than the recommended 20 seconds.

16% of attempts did not wet hands before applying soap; 4% skipped soap entirely.

62% of attempts did not use hand sanitizer after washing and drying.

Conclusion:

Even with available handwashing stations, most employees failed to follow proper procedures. The study highlights that training, monitoring, and process management are crucial alongside proper equipment to truly reduce contamination risks.

Common Problems in Handwashing Stations for Food Plants

Establish clear SOPs: Define precise handwashing and hand disinfection procedures in compliance with WHO and HACCP guidelines, including critical moments for hand hygiene.

Optimize handwashing stations: Consider automated or sensor-based systems where possible, or ensure manual stations are conveniently located and well-stocked with soap, sanitizer, and drying options.

Employee training: Regular training sessions to reinforce proper technique, coverage, and duration. Emphasize that each handwashing event matters.

Supervision and monitoring: Use periodic observation, CCTV, or electronic compliance logs to track adherence.

Integrate into HACCP/SSOP: Treat hand hygiene as a critical control point, just like equipment cleaning or environmental sanitation.

7-Step Handwashing Technique

Why a Handwashing Station in a Food Plant is Critical for Food Safety

Proper hand hygiene is not just about having handwashing stations—it is about compliance, process, and monitoring. Implementing the right procedures reduces the risk of cross-contamination, demonstrates professional standards, and strengthens trust with customers and auditors. For food plants aiming to be high-standard “source-level factories,” hand hygiene is a fundamental indicator of overall food safety culture.

References for Food Plant Handwashing Stations and Hygiene Practices

Observation of Food Handlers’ Hand Hygiene Behavior During Production at a Sandwich-Making Factory — Journal of Food Protection, 2024. (ScienceDirect)

A case study of food handler hand hygiene compliance in high-care and high-risk food manufacturing environments — PubMed, 2020s (PubMed)

Industry article on automated hand sanitizer systems in food factories (Foodjx)