| Name | Boot wash cleaning station |

| Model | PBW-61E |

| Clean type | Personnel shoes and boots hygiene |

| Voltage | 220V/50Hz |

| Power | 1000W |

| Safety protect | Overload 、Short circuit, 、 leakage protection |

| Waterproof | IP54 |

| Water inlet | 1/2″(DN15) |

| Water Outlet | OD50mm |

| Operation mode | Economic & self-cleaning |

| Control mode | Auto |

| Dimension | L16450xW955xH1410mm |

What is a boot washer?

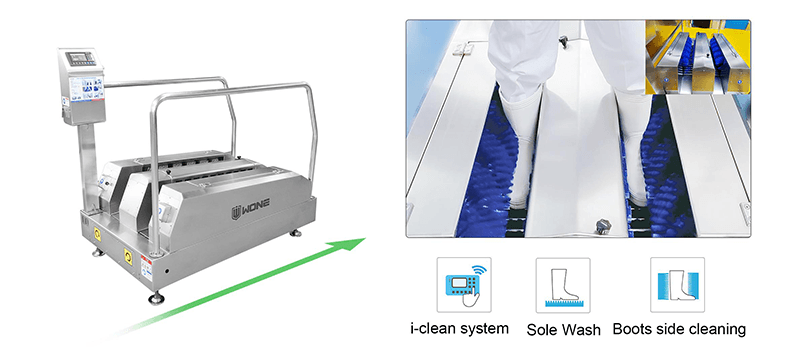

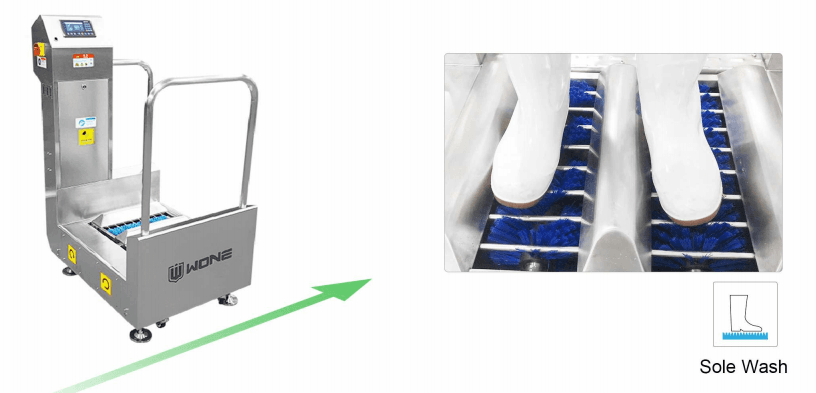

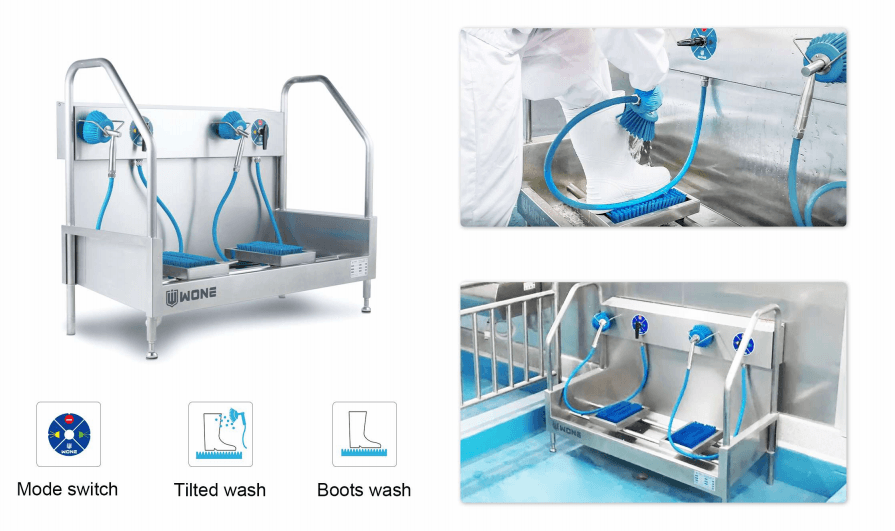

The Boot Washer PBW-61F is an automatic shoe cleaning station designed for food and beverage factories. Its sensor-activated brush rolls clean both the soles and sides of boots efficiently, saving water, energy, and cleaning chemicals while maintaining strict hygiene standards. Ideal for hygiene-sensitive facilities, it reduces contamination risks and enhances overall safety in production areas.

Key Features:

Automatic sensor operation activates brushes only when boots are detected.

Durable construction allows easy disassembly for maintenance.

Compact design fits into clean zones of factories or kitchens.

Efficient water and energy use reduces operational costs.

Who would use the boot washer?

1. Food Processing and Manufacturing Facilities

This is the most common and critical application for boot washers. In the food industry, including meat processing, poultry plant, dairy processing, seafood processing, baking factory, wine & beverage plants, etc., preventing cross-contamination is not just a best practice—it’s a legal requirement under standards like HACCP, FDA’s FSMA, and GMP.

2. Pharmaceutical and Medical Device Manufacturing

Sterility is non-negotiable in pharmaceutical production. These facilities operate under Good Manufacturing Practices (GMP), where even a single microorganism can compromise an entire batch of medicine or a sterile medical device.

3. Agriculture and Horticulture (Especially Indoor and High-Value)

Modern agricultural enterprises, particularly high-density livestock operations, hydroponic farms, and greenhouses, use boot washers as a first line of defense.

Applications of the boot washer in the Food Industry

A boot washer finds application in food processing and manufacturing industries, cleanrooms, packaging areas, and other hygiene-sensitive environments. They play a crucial role in preventing cross-contamination, maintaining cleanliness standards, and ensuring the integrity of products in these settings.

Entry/Exit Points: Installed at facility transitions to sanitize footwear when moving between clean and less-controlled areas

Why is the WONE boot washer?

There are many suppliers of boot washer cleaning machines on the market. A boot washer is a long-term investment, so choosing the right boot washer cleaning station is very important! Reasons for choosing WONE:

i-clean system:

- The smart manager of footwear hygiene in your food factory

Adjust cleaning time:

- Tailor the cleaning time and intensity to match specific zone requirements, from low-care to high-risk areas.

Adjust the dosage of the cleaning chemical:

- The system automatically controls the dosage of the cleaning chemical for every cycle, eliminating waste and ensuring effective sanitation.

Auto concentration of cleaning chemical:

- Integrated sensors maintain the auto concentration of the cleaning chemical in the tank, ensuring optimal efficacy and alerting staff for low levels.

Data-Driven Compliance: Logs usage data and cleaning cycles to simplify audits and demonstrate compliance with GMP, HACCP, and FDA regulations.

Please contact us if you are looking for a boot washer!

What types of boot washers does WONE have?

__________________________________________________________________________

___________________________________________________________________________

_____________________________________________________________________________

Frequently Asked Questions

Q: How does a boot washer differ from a shoe cleaner?

A: Boot washers are industrial-grade devices built for heavy-duty use in commercial settings, whereas shoe cleaners may be designed for lighter domestic or retail use.

Q: Can boot washers use disinfectants?

A: Yes, many systems support the injection of FDA-approved sanitizers or detergents for enhanced sterilization.

Q: Are they adaptable to existing entryways?

A: Yes, modular units can be customized to fit specific space constraints, including corner installations

Related Products & Resources:

Check out our Handwashing Station PHS-11T for complete hygiene solutions.

Learn more about food safety standards from FDA Food Safety Guidelines.