Product Overview

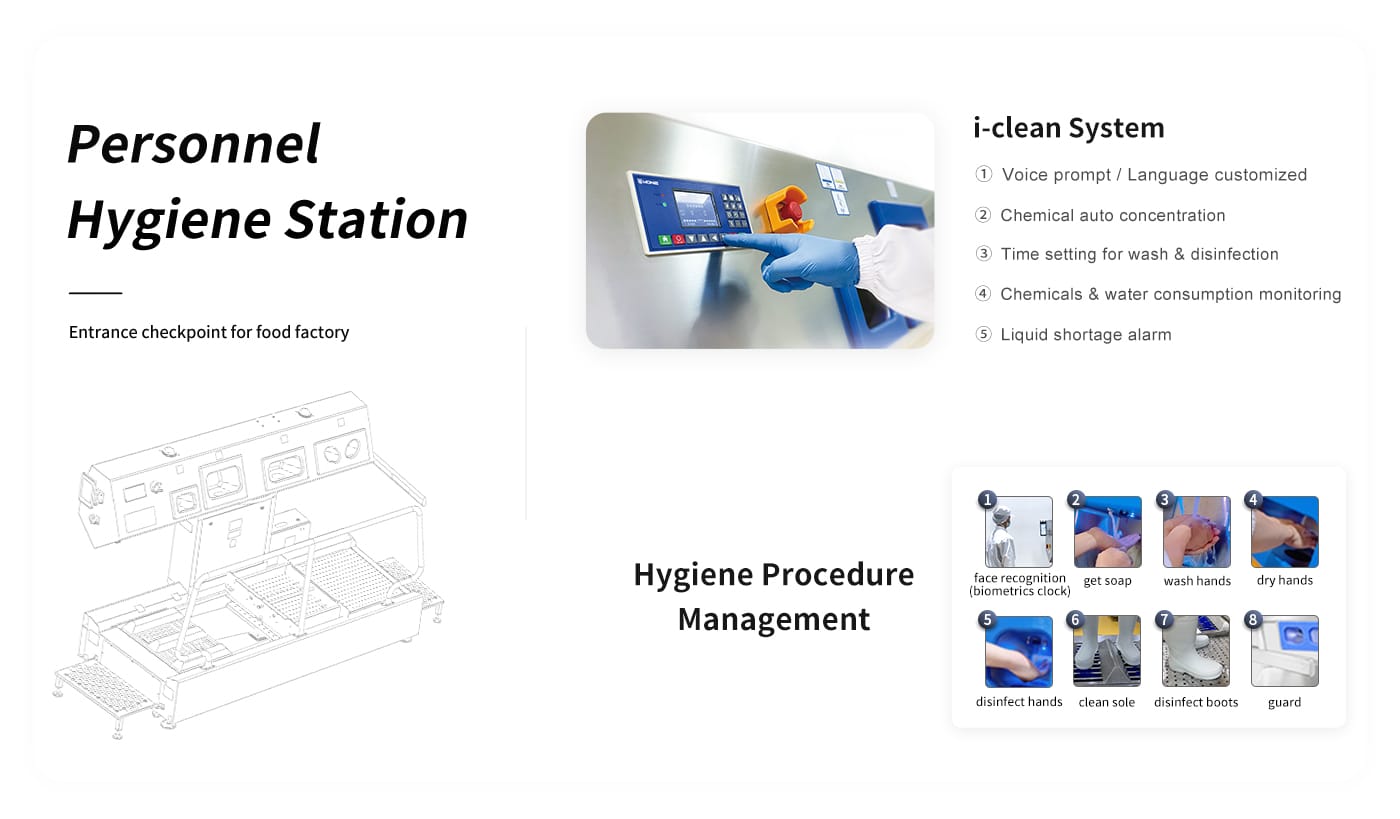

The PBW-25 Industrial Boot Washer is a robust, multi-functional hygiene station engineered for food factories and hygiene-critical production areas. It combines boot sole cleaning, boot disinfection, hand washing, hand drying, and hand sanitizing into a single, efficient system. By ensuring employees meet stringent hygiene standards before entering production zones, it improves compliance and operational efficiency.

This versatile industrial boot washer is ideal for:

-

Dairy and beverage production plants

-

Meat and poultry processing facilities

-

Cold storage and frozen food warehouses

-

Packaging areas and hygiene corridor access points

Moreover, as a trusted hygiene station manufacturer, the PBW‑25 integrates seamlessly with turnstile hygiene stations, enabling controlled access only after full hygiene compliance. It fully supports HACCP, GMP, IFS, and BRC standards, providing both safety and efficiency. For more information on hygiene compliance standards, see HACCP guidelines and Codex Alimentarius

Industrial Boot Washer Key Features & Benefits

Advanced Boot Cleaning & Disinfection

Equipped with rotating stainless steel brushes, the PBW-25 effectively removes dirt, debris, and microbial contaminants from footwear. In addition, its automatic disinfectant tray provides 99.9% microbial reduction on boot soles.

Adjustable brush speed and pressure allow it to handle various boot sizes, suitable for both manual boot wash station setups and boot washers food industry applications.

Usage Example:

At a dairy plant with 60 employees per shift, the PBW‑25 industrial boot washer reduced microbial contamination on floors by 35%, while allowing each employee to complete boot cleaning in approximately 3 minutes.

Integrated Hand Washing, Drying & Sanitizing Module

The PBW-25 provides touchless operation to prevent cross-contamination. Furthermore, its high-capacity hand hygiene module allows multiple employees to use it simultaneously, ensuring workflow efficiency.

Operational Flow Example:

-

Employees first step onto the boot washer; brushes clean and disinfect soles automatically.

-

Next, they wash hands under touchless sensors, followed by drying with the integrated air dryer.

-

Finally, touchless hand sanitizer applies a controlled dosage to complete the hygiene process.

Time per employee: ~2.5 minutes for complete boot and hand hygiene.

Durable, High-Throughput Industrial Boot Washer Design

Constructed from stainless steel 304 with IP54 waterproof sensors, the PBW‑25 operates reliably in wet, humid, and low-temperature environments. As a result, it can process up to 100 employees per hour, reducing contamination incidents while improving audit outcomes.

Scenario Example:

In a frozen meat processing plant, three PBW‑25 units handled three shift changes per day with zero downtime, maintaining hygiene standards and passing GMP inspections with no non-conformities.

Easy Installation & Maintenance of Industrial Boot Washer

The PBW-25 can be installed as a standalone unit or wall-mounted for space efficiency. Additionally, quick-access disinfectant trays and removable brushes simplify routine maintenance.

Recommended placement: factory entrances, changing rooms, and before turnstiles.

Routine care: refill disinfectant trays regularly, clean brushes weekly, and wipe sensors to maintain optimal performance.

Technical Specifications

| Name | Personnel Hygiene Station |

| Model | PBW-25 |

| Clean type | Personnel Hygiene |

| Voltage | 220V/50Hz |

| Power | 2200W |

| Safety protect | Overload、Short circuit.Leakage protection |

| Waterproof | IP54 |

| Water Inlet | 1/2”(DN15) |

| Water Outlet | 1″(DN25) |

| Hygiene practices functions | wash hand, dry hand, sanitize hand, clean sole, sanitize sole |

| Sanitizer/disinfectant volume | 2L |

| Dimension | L2990x W1045xH1640mm |

Industrial Boot Washer Applications & Use Cases

Dairy & Beverage Plants

-

Installed at entry points and hygiene corridors.

-

Ensures high foot traffic is managed efficiently while maintaining hand and boot hygiene.

Meat & Poultry Processing

-

Reduces microbial contamination in high-risk zones.

-

Maintains hygiene compliance even in wet, cold environments.

Cold Storage & Frozen Food Warehouses

-

IP54 sensors provide reliable operation in low temperatures and high humidity.

-

Additionally, PBW-25 integrates with sole cleaning machine food industry setups for streamlined hygiene workflow.

Internal Links:

Installation Guide for Industrial Boot Washer

-

Install at 1.1–1.2 m height for ergonomic use.

-

Connect to 220V / 50Hz power supply.

-

Maintain at least 50 cm from strong lights or heat sources.

-

Place units before turnstiles, changing rooms, and production entry points.

-

Refill disinfectant trays regularly.

-

Weekly maintenance: clean brushes, sensor windows, and surrounding floors.

Case Studies (Simulated Data)

Case 1 — Dairy Factory, Netherlands

-

Two PBW-25 units installed at main entry points.

-

Results:

-

60 employees per shift processed in 3 minutes each

-

Microbial contamination on floors reduced by 35%

-

100% HACCP compliance

-

Case 2 — Frozen Meat Plant, Germany

-

Four units installed across three entrances.

-

Results:

-

90 employees per shift completed hygiene process in under 4 minutes

-

Sensor performance stable at -2°C to 4°C

-

Zero non-conformities during GMP audit

-

FAQ — Industrial Boot Washer PBW-25

Q1: Can PBW-25 operate in cold storage environments?

A1: Yes, IP54 stainless steel body and waterproof sensors ensure reliable performance in cold, humid conditions.

Q2: What disinfectants are compatible?

A2: Liquid or alcohol-based sanitizers are recommended; gels should be avoided.

Q3: Can PBW-25 integrate with turnstiles?

A3: Yes, fully compatible with turnstile hygiene station and access control systems.

Q4: How often should brushes and disinfectants be replaced?

A4: Brushes monthly; disinfectants refilled according to factory schedule.

Q5: What is the hourly capacity?

A5: Up to 100 employees per hour, depending on workflow.