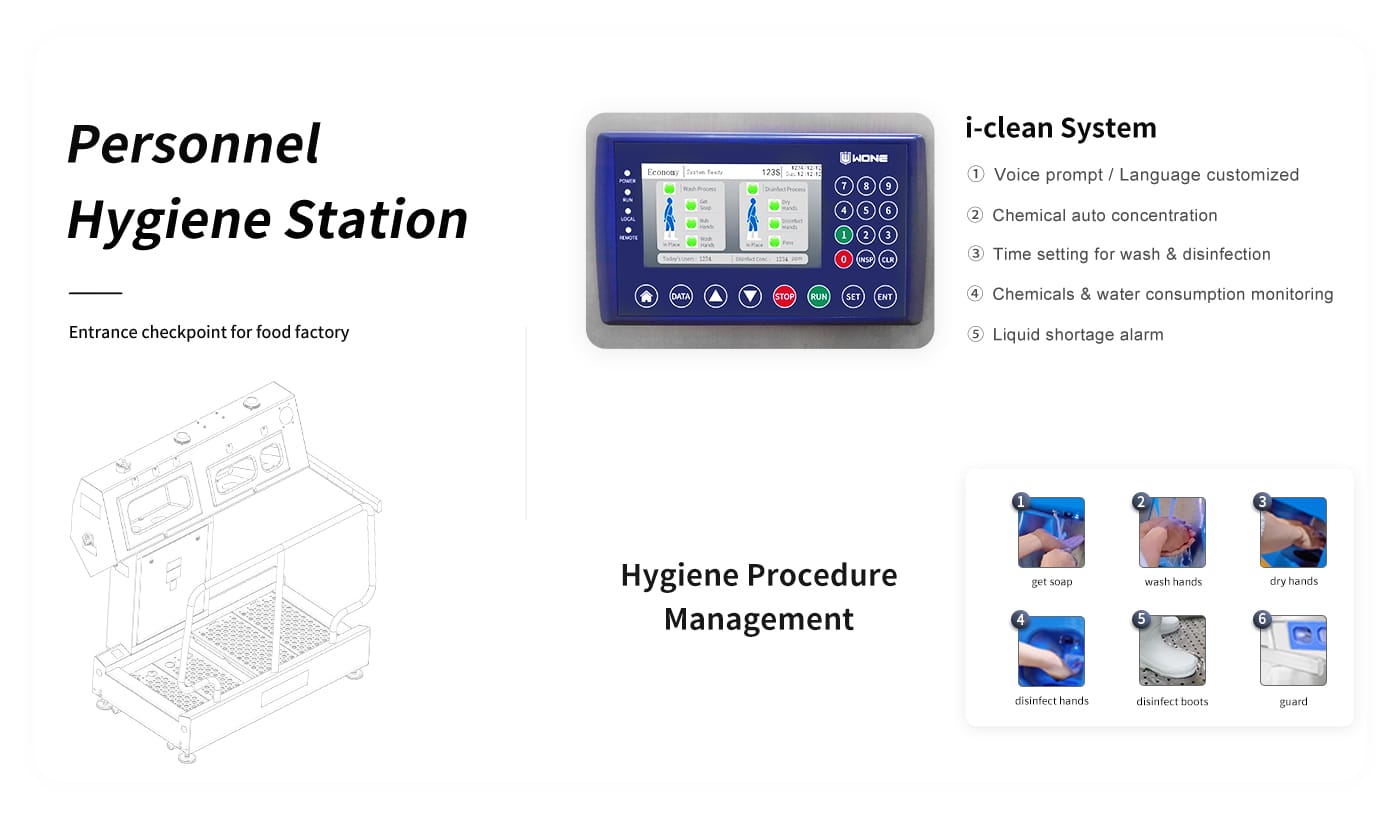

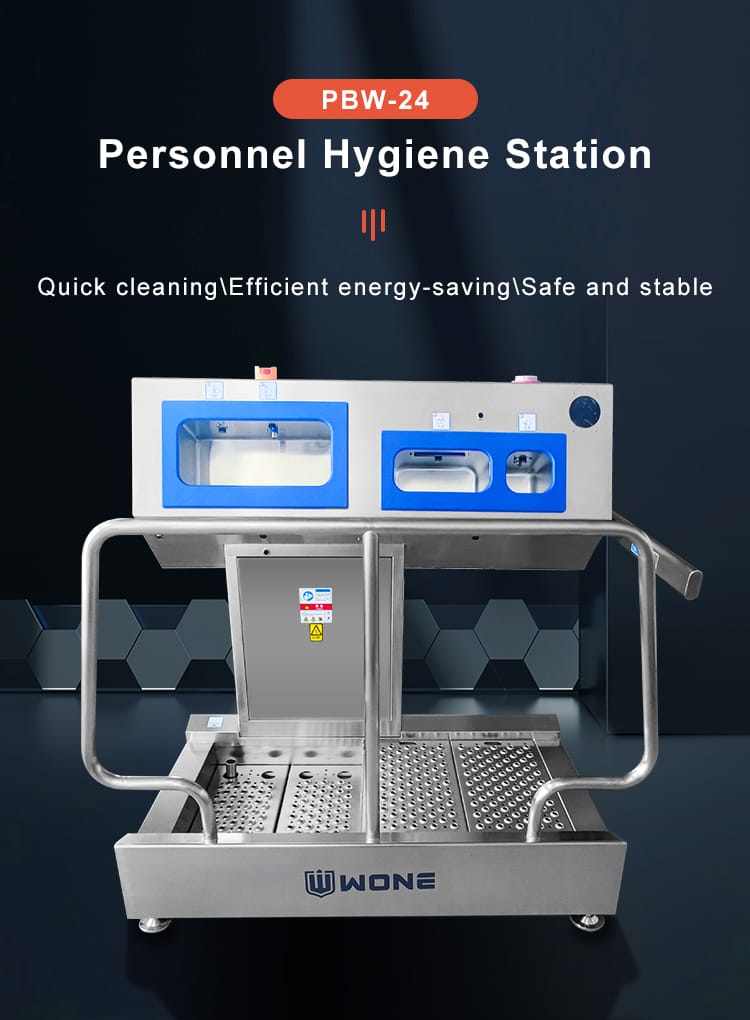

Safe, Fast, and Complete Hygiene Station PBW‑24 for Food Factories

Hygiene Station PBW‑24 is an all-in-one solution for food factories and high-standard production areas. It provides hand washing, hand drying, hand sanitization, boot cleaning, and access control with a turnstile, ensuring maximum hygiene compliance and reducing cross-contamination risks.

Key Features of Hygiene Station PBW‑24

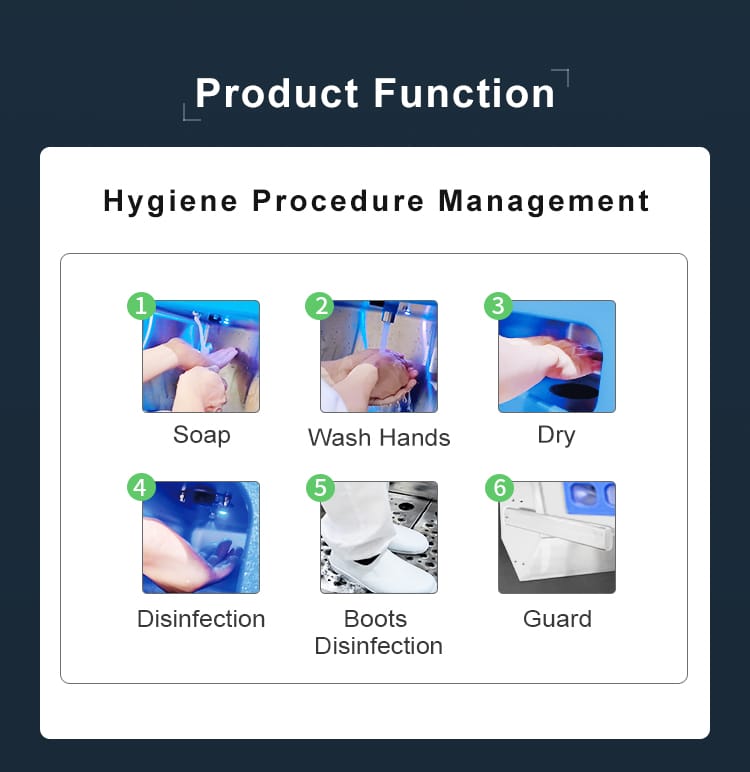

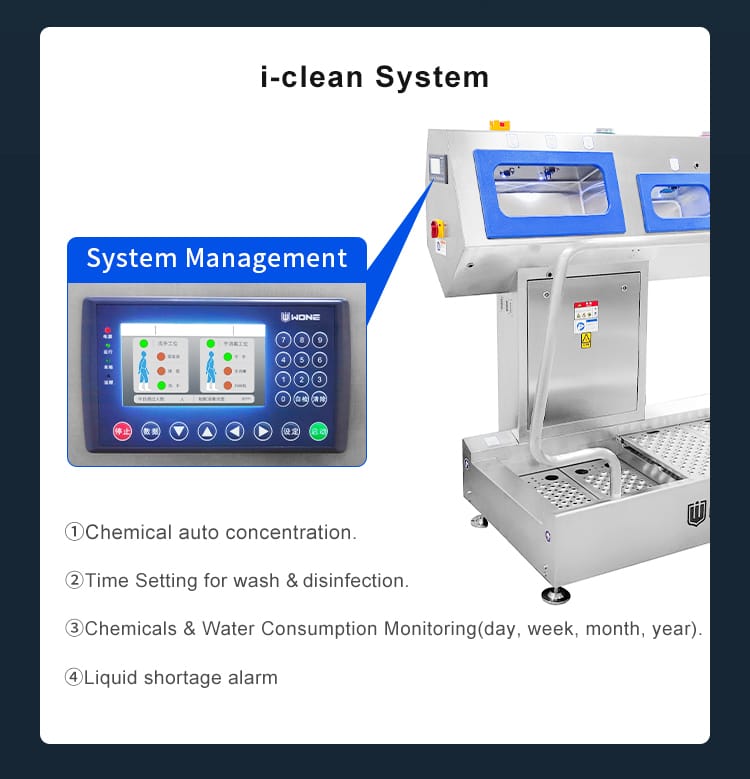

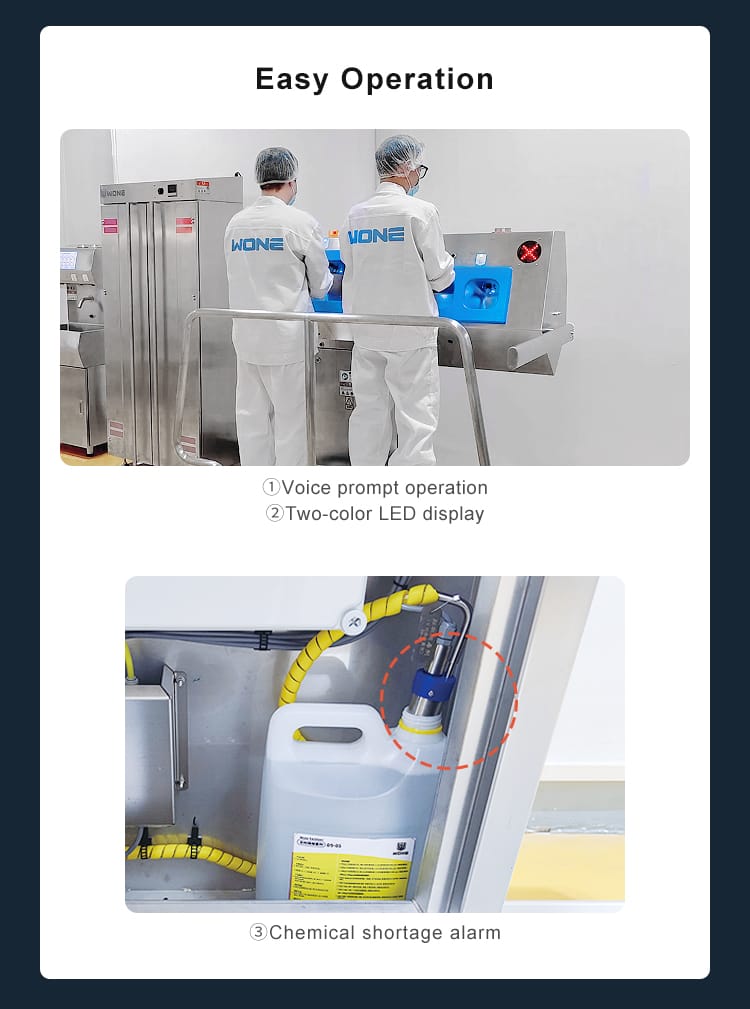

Automatic Hand Washing – Thorough hand cleaning with touch-free operation.

Fast Hand Drying – Hygienic and quick drying to maintain workflow efficiency.

Hand Sanitization – Alcohol or quaternary ammonium-based disinfection.

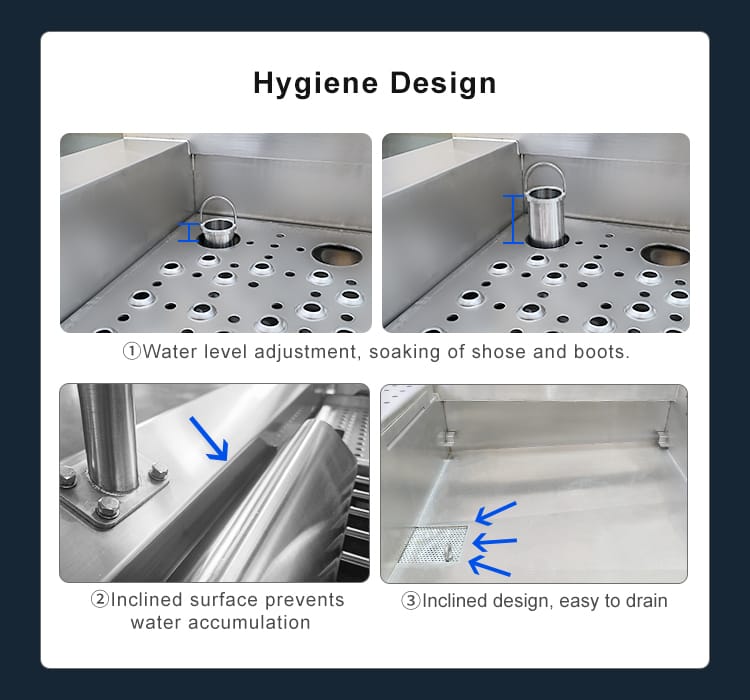

Boot/Shoe Sole Cleaning – High-efficiency brushes for footwear hygiene.

Turnstile Access Control – Ensures only sanitized employees can enter production areas.

Durable Stainless Steel Design – Easy to clean and resistant to corrosion.

Fast Operation – Complete all hygiene steps in under 30 seconds.

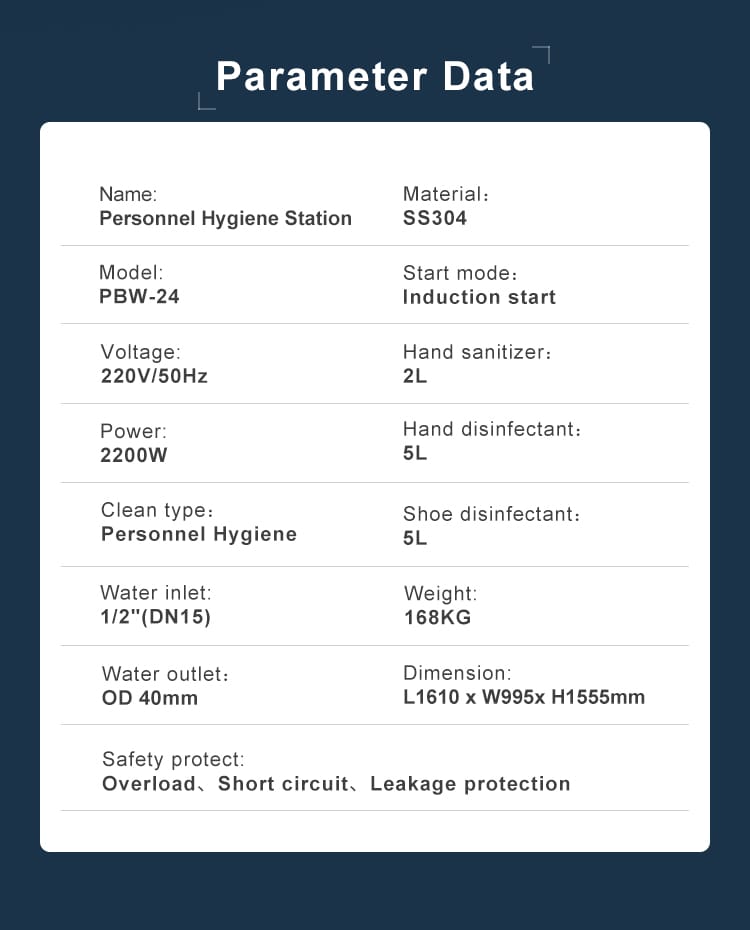

Technical Specifications of Hygiene Station PBW‑24

| Name | Personnel Hygiene Station |

| Model | PBW-24 |

| Clean type | Personnel Hygiene |

| Voltage | 220V/50Hz |

| Power | 2000W |

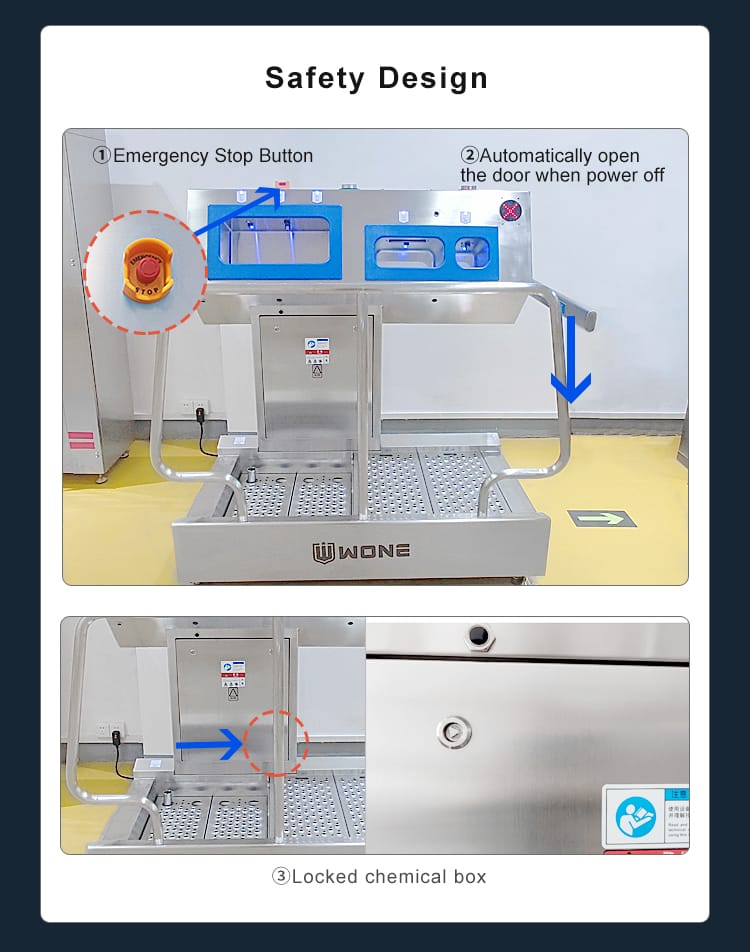

| Safety protect | Overload、Short circuit、Leakage protection |

| Waterproof | IP54 |

| Water inlet | 1/2″(DN15) |

| Water Outlet | OD40mm |

| Operation mode | Economic & Force |

| Sanitizer volume | 2L |

| Dimension | L1610x W995x H1555mm |

Applications and Use Cases of Hygiene Station PBW‑24

Meat Processing Plants: Employees wash, dry, and sanitize hands, clean boots, and pass through turnstiles to enter production areas safely.

Dairy Factories: Ensures milk handling areas remain hygienic with complete hand and footwear sanitation.

Beverage Production Facilities: Fast hygiene cycle keeps production lines running efficiently.

Installation & Case Study of Hygiene Station PBW‑24

Installation Steps:

Place PBW‑24 at the facility entrance.

Connect water supply, sanitizer, and electricity.

Integrate turnstile access control.

Test all functions: hand wash, hand dry, sanitization, boot cleaning.

Ready for daily operation.

Case Study:

Client: Southeast Asia Seafood Processor

Problem: Poor hygiene compliance and HACCP non-conformities.

Solution: Installed PBW‑24 hygiene stations with integrated turnstiles.

Results after 6 weeks:

Microbial counts ↓ 42%

Zero HACCP non-conformities

Product rejection rates ↓ 28%

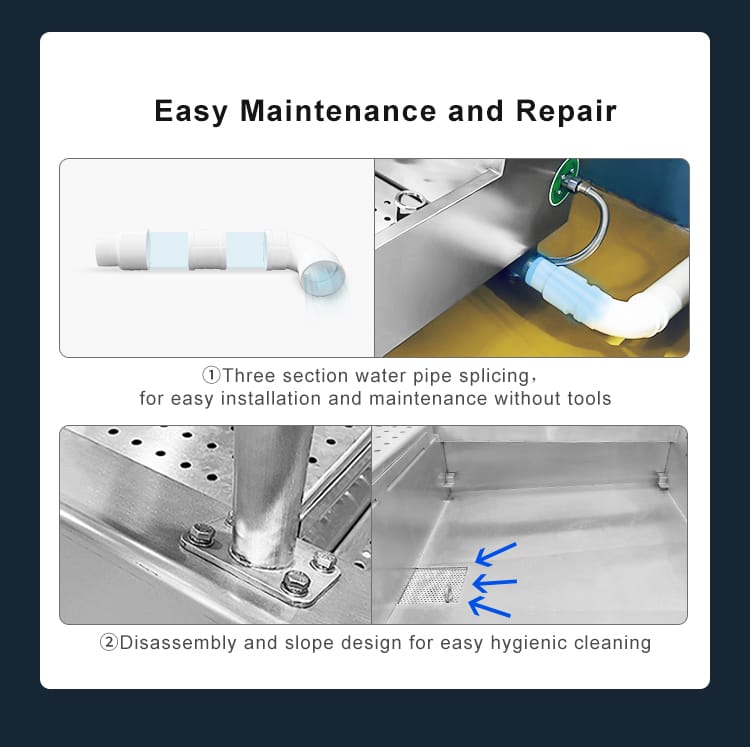

Detailed images

FAQ

Q1: Which shoe types are compatible with PBW‑24?

A1: Supports standard protective shoes and rubber boots.

Q2: How often should the hygiene cycle be performed?

A2: Each employee should complete the full cycle before entering production areas.

Q3: Does PBW‑24 require electricity?

A3: Yes, operates on 220V/50Hz power.

Q4: Can different sanitizers be used?

A4: Yes, quaternary ammonium sanitizers are compatible.

Q5: How to maintain PBW‑24?

A5: Clean brushes weekly, refill sanitizer, inspect turnstile monthly.

Call to Action

“Request a Quote Today for Hygiene Station PBW‑24”

PBW‑24 is fully compliant with internationally recognized food safety standards, including HACCP and ISO 22000. Using PBW‑24 for hand washing, hand drying, hand sanitization, boot cleaning, and turnstile access control ensures your facility meets critical hygiene requirements and reduces the risk of cross-contamination. For practical implementation, you can see how we integrate Hygiene Station PBW‑24 in different production lines in our Industry Applications Page and read detailed hygiene station setups in our Blog on Designing Food Factory Hygiene Stations.

Button: “Request Pricing / Consultation