APPLICATION

POULTRY Processing

The poultry processing faces significant hygiene challenges, particularly in meeting international food safety standards such as HACCP, GMP, and ISO. Our hygiene equipment provides innovative solutions to reduce cross-contamination risks, enhance production efficiency, and comply with industry regulations.

Industry Pain Points

Poultry processing plants are high-risk areas for bacterial growth, particularly during slaughtering, feather removal, and packaging stages. Pathogens like Salmonella and Listeria are easily spread through manual handling, shoes, and equipment, leading to potential cross-contamination and food safety issues. Traditional cleaning methods are often inefficient, unable to thoroughly clean critical areas. To mitigate these risks, investing in effective hygiene equipment is essential to improve food safety and operational efficiency. Our hygiene solutions are designed specifically to address these challenges, ensuring a safer, more efficient production environment.

Why Hygiene Equipment is Necessary

The hygiene of a poultry processing environment directly impacts the safety and quality of the products. Our hygiene equipment addresses the following key issues:

Reducing Bacterial Spread: Effective shoe sole sanitizers and hand sanitization stations reduce bacterial entry into the processing area.

Increasing Cleaning Efficiency: Automated foam cleaning systems and air disinfectants significantly improve cleaning speed, reducing labor costs.

Compliance with Standards: All our equipment meets HACCP, GMP, and ISO standards, ensuring your factory meets international food safety regulations.

Process Flow & Critical Control Points

The following table outlines the key stages in poultry processing where hygiene equipment plays a vital role in maintaining safety:

| Stage | Hygiene Risk | Required Equipment | Critical Control Points |

|---|---|---|---|

| Slaughtering | Cross-contamination from animal to surface | Hand Sanitizer, Shoe Sole Sanitizer | Ensure all workers sanitize before entry |

| Feather Removal | Bacteria on feathers | Foam Cleaning System, Hand Sanitizer | Clean all equipment and surfaces regularly |

| Packaging | Contamination from packaging materials | Air Disinfection, Hand Sanitizer | Sanitize all packaging surfaces |

By incorporating hygiene equipment at these critical points, the risk of contamination can be significantly reduced, ensuring a safe and hygienic production environment.

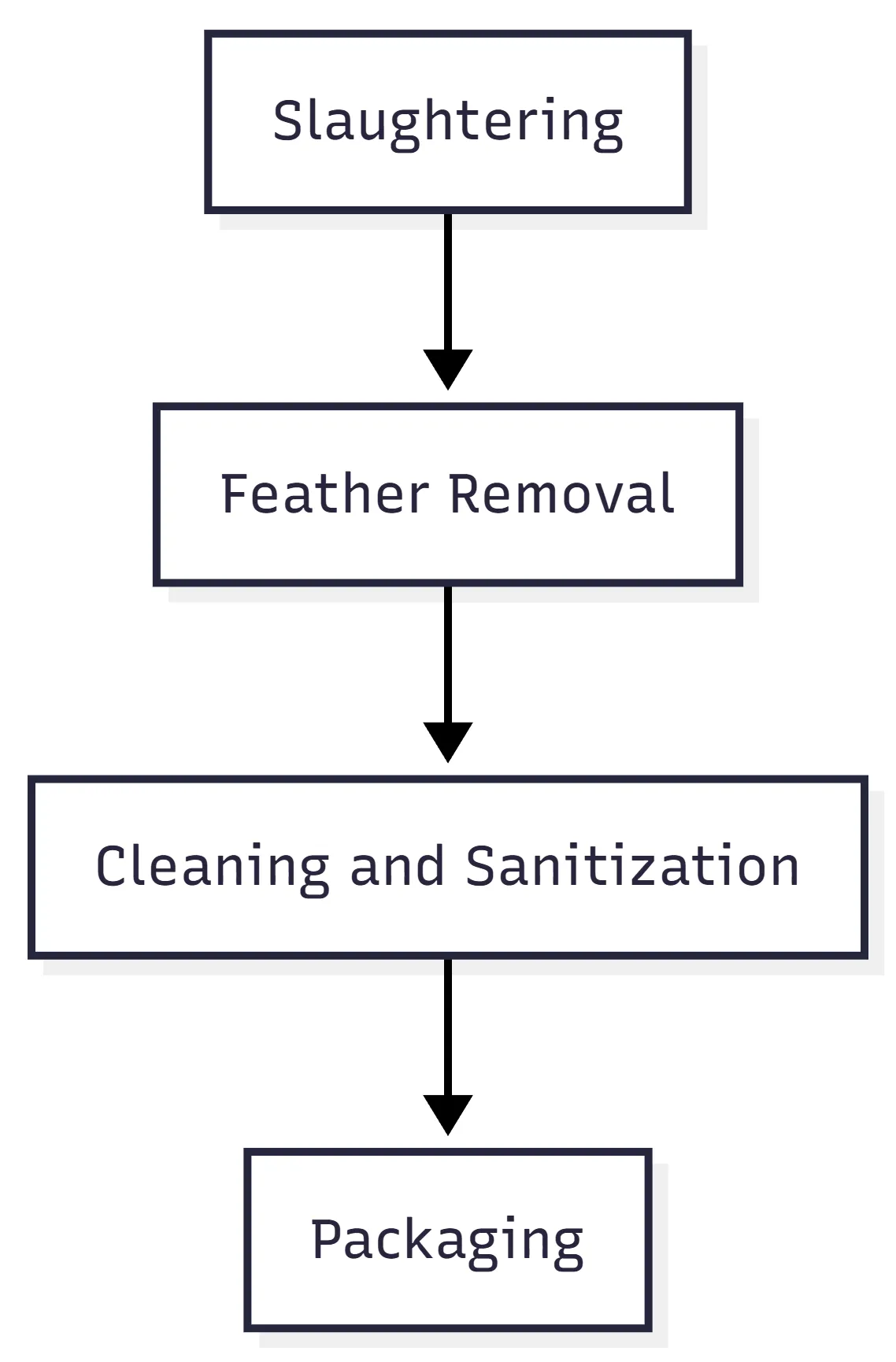

Usage Scenario (Flowchart)

Here is an HTML flowchart illustrating the hygiene process in a poultry processing plant:

This flowchart visually represents the hygiene process during poultry processing, highlighting the critical stages where hygiene equipment is essential.

Case Study: Poultry Processing Plant Hygiene Improvement

Background:

A poultry processing facility was struggling with bacterial contamination, particularly during the slaughtering and packaging stages. They experienced regular health and safety audits that highlighted hygiene deficiencies, which led to production delays and increased costs.

Solution:

The plant implemented our full hygiene solution, including:

Hand Sanitizers at all entry points.

Shoe Sole Sanitizers for workers.

Automated Foam Cleaning Systems to sanitize equipment.

Air Disinfection Systems to prevent airborne bacteria.

Results:

Reduction in Cross-Contamination: Pathogen levels dropped by 40% within the first three months.

Improved Efficiency: Cleaning time was reduced by 30%, allowing workers to focus on production.

Compliance: The plant passed all HACCP and ISO audits with no issues, increasing customer trust.

Regulations and Standards Compliance

Our equipment is designed to meet the following regulations:

HACCP: Ensures food safety by identifying and controlling food hazards.

GMP: Guarantees product quality and safety, aligning with global production standards.

ISO 22000: Food safety management system certification, ensuring compliance with international food safety practices.

Related Products

Blog Links

Conclusion

Our poultry processing hygiene equipment helps mitigate risks, improve operational efficiency, and ensure compliance with international standards. By integrating our solutions, poultry processing plants can reduce contamination, enhance production, and increase product safety, all while staying competitive in the market.

External Resources

To further enhance your knowledge about hygiene solutions in the poultry processing industry, here are some valuable resources:

FDA – Food Safety and Inspection Services (FSIS) – The official site for food safety regulations, providing guidelines that poultry processors must follow to maintain food safety.

HACCP International – Food Safety Certification – A leading organization for HACCP certification, offering resources on how to implement HACCP standards in food processing.

ISO 22000 Food Safety Management – Official ISO page for understanding food safety management systems and how to comply with international food safety standards.

These external resources will provide you with additional insights into the best practices and certifications that are essential for ensuring the safety and hygiene of your poultry processing facility.