APPLICATION

WIne & Beverage

Beverage Processing Hygiene Solutions

Maintaining Beverage Processing Hygiene in beverage plants is critical to prevent microbial contamination, ensure product safety, and comply with food safety regulations. Hygiene risks exist at multiple stages of production, making it necessary to implement specialized equipment and clearly defined Critical Control Points (CCP) throughout the process.

Key Hygiene Risk Points in Beverage Processing

Raw Material Receiving – Ingredients may carry microbes or contaminants from suppliers.

Production Area Entry – Cross-contamination from footwear or clothing is common.

Employee Hygiene & Gowning – Poor personal hygiene can introduce pathogens.

Pre-Processing Cleaning – Equipment surfaces may harbor microbes if not properly cleaned.

Mixing, Filling & Packaging – Direct contact with product increases contamination risk.

Storage & Warehousing – Microbial growth can occur if temperature and cleanliness are not controlled.

Essential Equipment for Beverage Processing Hygiene

To control these risks,Beverage Processing Hygiene specialized equipment is required at each stage:

Hand Wash Stations – Ensure that all staff sanitize hands before entering production areas.

Boot & Sole Washers – Prevent contaminants from being carried in on footwear.

Hygiene Sluices – Control entry and exit points, enforcing sanitation protocols.

Foam Cleaning Systems & Automated Sanitation – Regularly disinfect surfaces and equipment without manual errors.

Air Sterilizers – Reduce airborne microbial contamination in critical areas.

Personal Hygiene Stations – Provide gloves, aprons, and sanitizer dispensers for employees.

Critical Control Points (CCP) for Beverage Hygiene

| Stage | CCP | Monitoring & Equipment |

|---|---|---|

| Raw Material Receiving | Microbial contamination | Hand wash stations, sanitized surfaces |

| Production Area Entry | Cross-contamination | Boot & sole washers, hygiene sluices |

| Employee Hygiene & Gowning | Personal contamination | Personal hygiene stations, gloves, aprons |

| Pre-Processing Cleaning | Equipment contamination | Foam cleaning systems, automated sanitation |

| Mixing & Filling | Product contamination | Automated foam cleaning, air sterilizers |

| Packaging | Product contamination | Sanitized packaging lines, quality checks |

| Storage & Warehousing | Microbial growth | Temperature control, periodic cleaning |

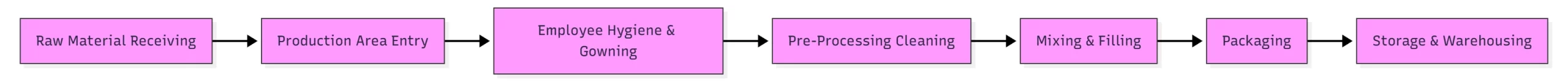

Beverage Processing Hygiene Flow Diagram

This flowchart illustrates how hygiene controls Beverage Processing Hygiene are integrated throughout the beverage production process.

Equipment Usage Scenarios for Beverage Hygiene

Hand Wash Stations – At entry points, changing rooms, and near filling lines.

Boot Washers & Hygiene Sluices – At production area entrances to prevent cross-contamination.

Foam Cleaning Systems – Applied on mixing tanks, conveyors, and packaging lines.

Air Sterilizers – Installed in high-risk zones like filling and packaging areas.

Personal Hygiene Stations – Located in changing rooms and staff entry points.

Internal Links to Products

For more details,Beverage Processing Hygiene check our related equipment pages: