APPLICATION

CENTRAL KITCHEN

Industry Pain Points Analysis

Central Kitchen Hygiene Solutions are essential for maintaining high food safety standards, particularly in large-scale food production environments. By implementing effective hygiene practices, central kitchens can minimize contamination risks, meet regulatory requirements, and improve operational efficiency. This case study highlights how a hygiene overhaul can lead to significant improvements in food safety and efficiency.

Cross-Contamination: Raw materials and finished products may come into contact, transferring harmful bacteria or allergens.

Inconsistent Cleaning: Manual cleaning methods can be insufficient, leaving certain areas, especially corners or hidden parts of equipment, under-sanitized.

Regulatory Compliance Pressure: Meeting the rigorous standards of food safety regulations like HACCP, GMP, and ISO is often difficult without the right hygiene solutions.

These pain points lead to increased risks of foodborne illnesses, product recalls, and non-compliance with food safety laws. The absence of proper sanitation systems only exacerbates these issues, making hygiene equipment a necessary investment for every central kitchen.

Hygiene Risk Points and Key Control Areas

| Hygiene Challenge | Risk Point Description | Consequences |

|---|---|---|

| Cross-Contamination | Raw and cooked products coming into contact or through improper handling. | Bacterial spread, foodborne illnesses. |

| Worker Hygiene | Employees touching food without sanitizing hands or boots. | Increased risk of contamination. |

| Sanitation of Equipment | Poorly sanitized surfaces, utensils, and machines. | Surfaces can harbor bacteria, leading to contamination. |

| Cleaning Efficiency | Inadequate cleaning time and methods lead to poor sanitization. | Non-compliance with hygiene standards. |

| Waste Management | Accumulation of organic waste or improperly handled waste. | Odor, pests, and contamination risks. |

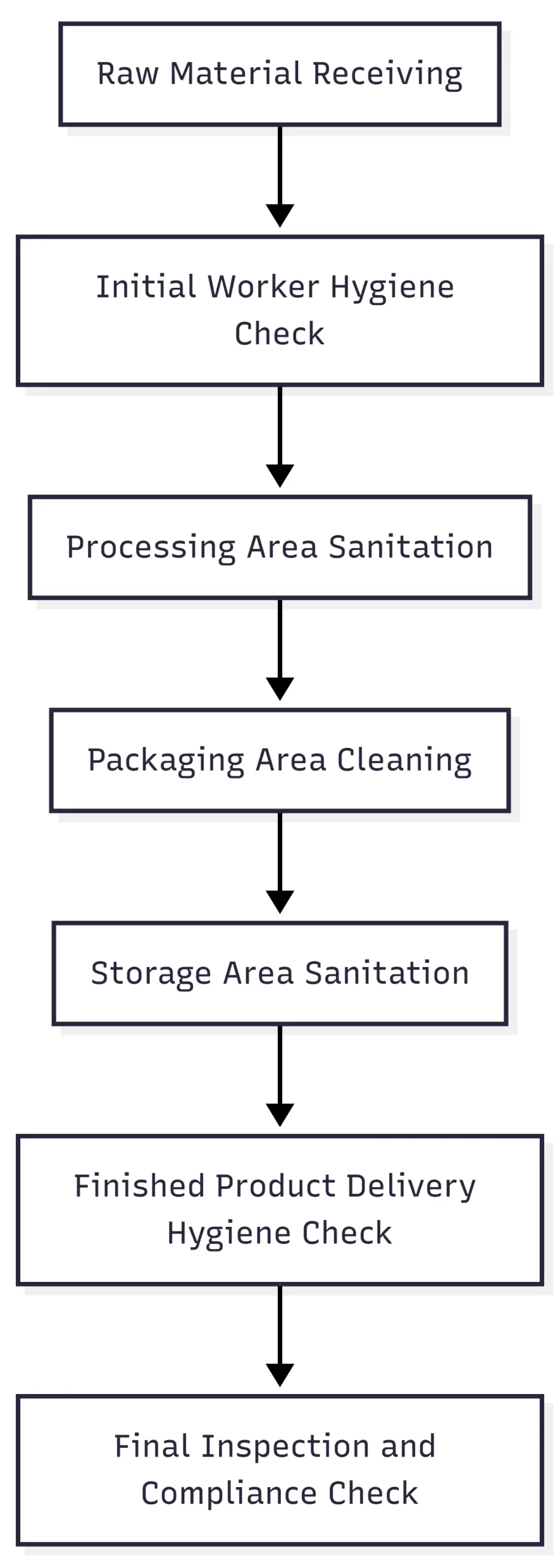

Process Flow and Hygiene Control

A clean and sanitized food preparation environment depends on a well-managed workflow. Below is a flowchart that shows the critical stages where hygiene control is most important.

This flow chart highlights where hygiene is most critical in a central kitchen, from raw material receiving to final product delivery. Each stage must meet strict sanitation standards to ensure food safety.

Regulatory Compliance: HACCP, GMP, and ISO Standards

Central kitchens must adhere to food safety regulations to ensure both product safety and operational efficiency. Below is a breakdown of key regulations and their relevance to hygiene control.

| Regulation | Description | Relevance to Hygiene Equipment |

|---|---|---|

| HACCP (Hazard Analysis and Critical Control Points) | A systematic approach to identify food safety hazards and their control at critical points. | Requires effective sanitation at every critical control point (e.g., hand sanitizers, boot washers). |

| GMP (Good Manufacturing Practices) | Standards for ensuring products are produced and controlled under hygienic conditions. | Emphasizes regular cleaning and disinfecting, especially in processing and storage areas. |

| ISO 22000 (Food Safety Management) | Sets out the criteria for a food safety management system. | Focuses on preventing contamination, which can be achieved through robust hygiene practices. |

By complying with these standards, central kitchens reduce the risk of contamination and protect public health.

Hygiene Risk Management: Effective Solutions

Case Study: ABC Central Kitchen – A Hygiene Overhaul

Client: ABC Central Kitchen

Industry: Food Production

1. The Challenge

ABC Central Kitchen, a large facility producing pre-packaged meals, faced significant hygiene issues:

Cross-Contamination: Raw meats and vegetables were contaminating finished products like salads and sandwiches.

Regulatory Warnings: The kitchen received warnings for non-compliance with HACCP and GMP standards.

Inefficient Cleaning: Manual cleaning efforts were slow and inconsistent, leading to lingering contaminants.

These issues put the kitchen at risk of foodborne illness outbreaks and regulatory fines.

2. The Solution

The kitchen implemented a comprehensive hygiene strategy:

Automated Boot Washers at entry points to prevent contaminants.

Hand Sanitizing Stations in high-risk areas.

UV Light & Disinfectant Surface Sanitization to reduce manual labor and improve consistency.

Employee Training on hygiene protocols.

Hygiene Monitoring System to track real-time sanitation levels and ensure compliance.

3. The Results

Zero Cross-Contamination: Contamination incidents dropped to zero.

100% Regulatory Compliance: Full compliance with HACCP and GMP standards.

Improved Efficiency: Cleaning time was reduced by 40%, increasing overall productivity.

Better Staff Morale: Empowered staff with improved working conditions and hygiene practices.

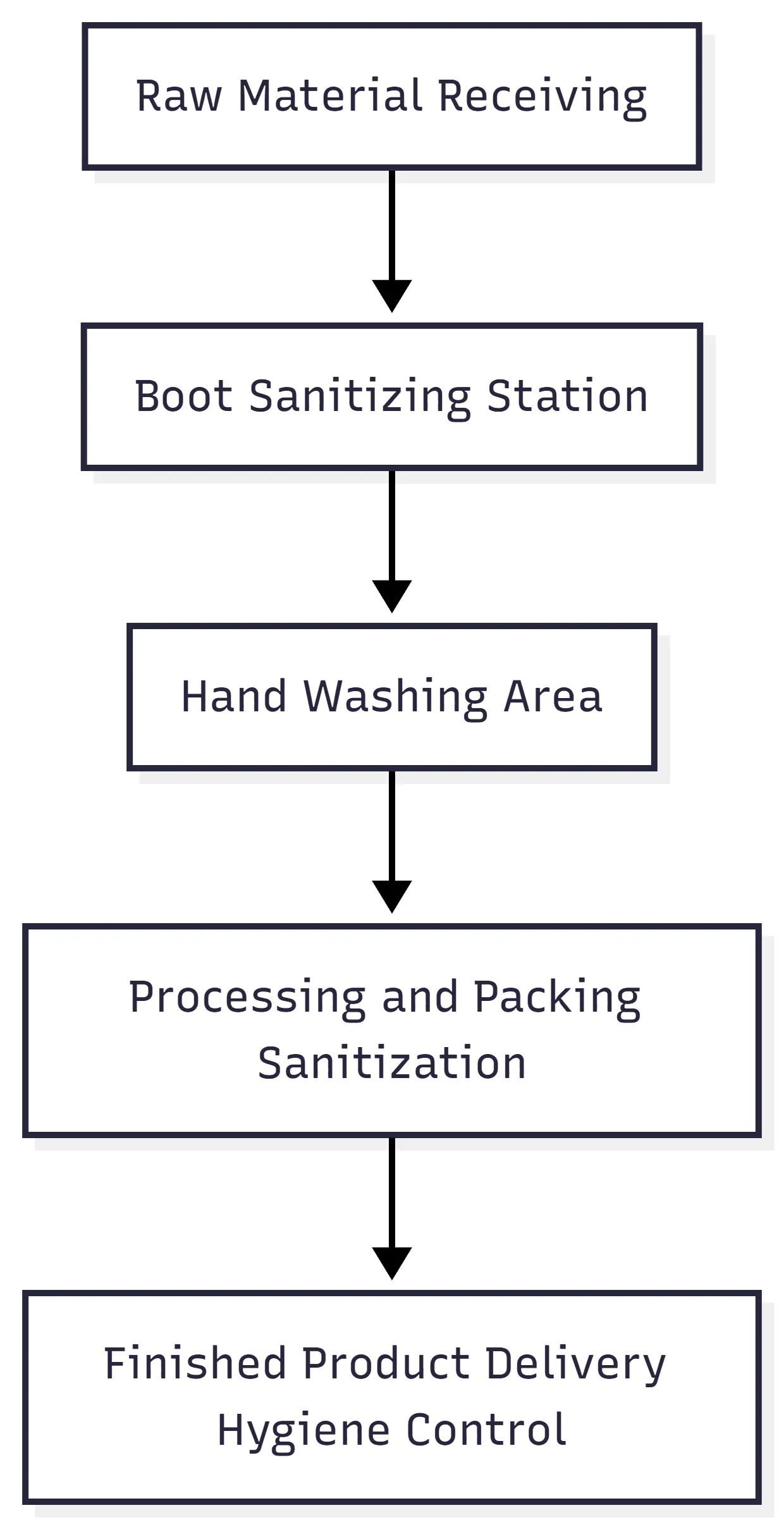

Visuals and Diagrams: Hygiene Equipment in Action

Hygiene Process Diagram

Key Hygiene Control Points in a Central Kitchen:

Boot Sanitizing Stations: Prevent contaminants from being tracked through different zones.

Hand Washing and Disinfection: Workers clean their hands frequently to avoid direct contamination.

Surface Disinfection: All equipment, tools, and surfaces are sanitized regularly to prevent cross-contamination.

Conclusion

The central kitchen sector faces significant challenges when it comes to maintaining hygiene. Addressing these challenges effectively requires a well-thought-out approach that includes stringent hygiene control points, efficient sanitation processes, and compliance with industry standards like HACCP, GMP, and ISO. By adopting these strategies, central kitchens can improve food safety, minimize contamination risks, and increase operational efficiency.