Hygiene Station PBW‑23 – Product Overview

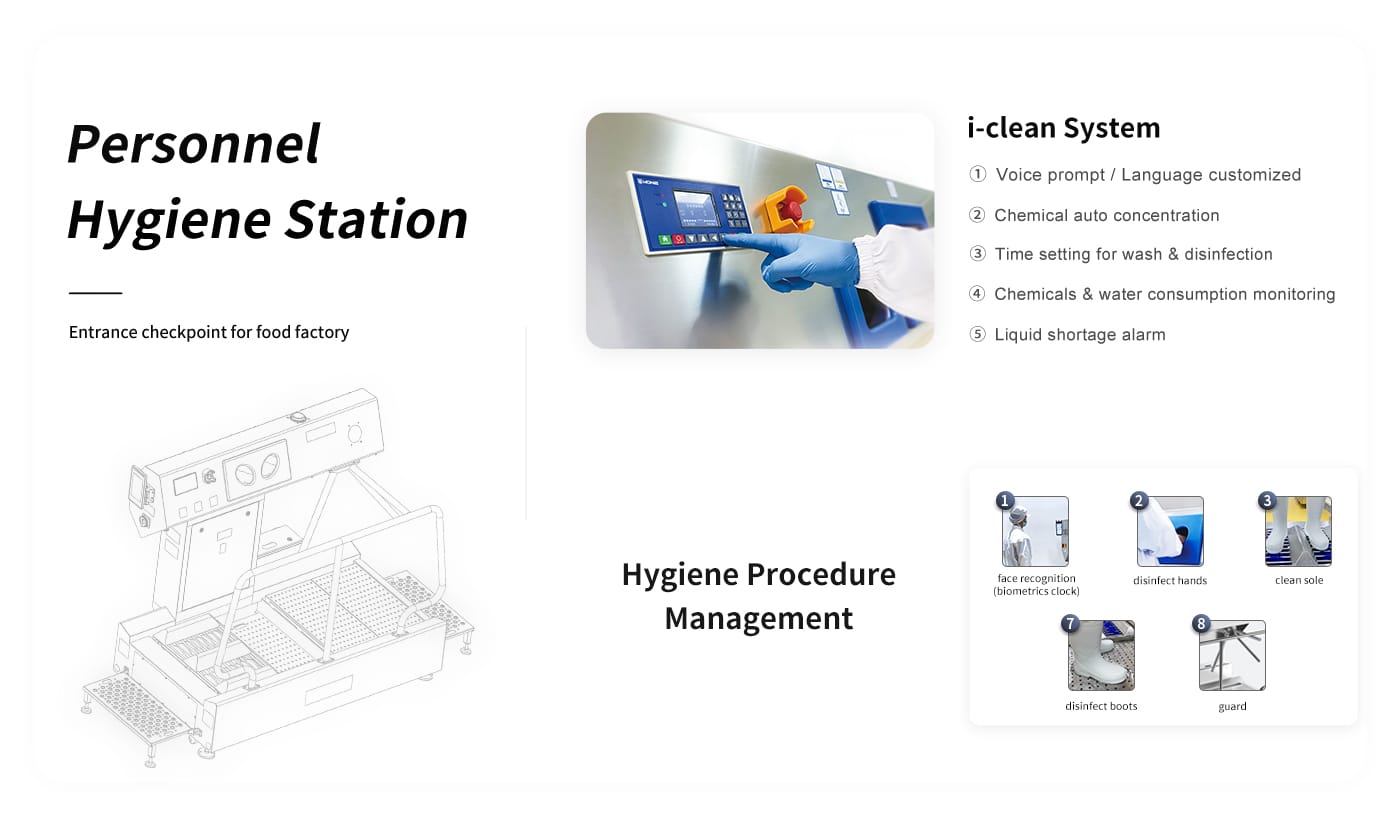

The Hygiene Station PBW‑23 is a fully integrated touchless hand disinfection and boot cleaning system designed for food processing facilities that require strict hygiene control. Combining automatic hand sanitizing, mechanical boot sole cleaning, and turnstile access control, However,this hygiene station ensures every worker follows mandatory sanitation procedures before entering production areas.

Moreover, its compact yet durable design improves personnel hygiene, Examples,minimizes contamination risks, and supports compliance with HACCP, BRCGS, ISO 22000, and GMP standards. Additionally, the PBW-23 is ideal for meat, poultry, seafood, dairy, beverage, bakery, and cold-room environments.

For additional solutions, explore our Food Processing Hygiene Solutions page and related PBW series hygiene stations.

For additional hygiene solutions, explore our Food Processing Hygiene Solutions page and related PBW series hygiene stations.

Key Features & Benefits of the Hygiene Station PBW‑23

1. Touchless Hand Disinfection Module

Infrared sensors automatically dispense sanitizer, reducing cross-contamination. Furthermore, it delivers consistent sanitizer dosage for every user, ensuring compliance in high-traffic areas.

2. Automatic Boot Sole Cleaning

High-strength rotating brushes remove dirt, dust, and residues effectively. In addition, an integrated disinfectant dosing system guarantees reliable hygiene for both wet and dry areas, making it perfect for meat, poultry, seafood, bakery, and beverage production zones.

3. Turnstile Access Control

The turnstile unlocks only after hand disinfection and boot cleaning, preventing unauthorized access. Consequently, it ensures 100% hygiene compliance. Moreover, optional RFID/ID card integration allows traceability and audit readiness.

4. Durable Stainless Steel Construction

Built from 304/316 stainless steel, it resists corrosion and supports daily high-pressure cleaning. Therefore, the PBW-23 performs reliably in wet, low-temperature, and high-humidity environments.

5. High-Traffic Operation

Designed for continuous operation during shift changes, the PBW-23 requires minimal maintenance. Additionally, sanitizer refills are easy, and its robust mechanical components support long-term use.

Technical Specifications of PBW‑23 Hygiene Station

| Name | drehkreuz desinfektion Personnel Hygiene Station |

| Model | PBW-23 |

| Clean type | Personnel Hygiene |

| Voltage | 220V/50Hz |

| Power | 1200W |

| Safety protect | Overload、Short circuit、Leakage protection |

| Waterproof | IP54 |

| Water inlet | 1/2″(DN15) |

| Water Outlet | 1″(DN25) |

| Operation mode | Economic & Force |

| Sanitizer volume | 5L |

| Dimension | L2470x W1045x H1510mm |

PBW-23 Hygiene Station Applications & Use Scenarios

Food Processing Plants

In meat and poultry plants, the Hygiene Station PBW‑23 ensures all personnel comply with hygiene protocols.

Meat & Poultry Production

Boot soles and hands often carry protein residues and bacteria. Therefore, the PBW-23 removes contaminants effectively before workers enter clean areas, supporting HACCP compliance.

Seafood Factories

Wet and cold floors promote bacterial growth. As a result, this hygiene station provides stable disinfection performance, even in low-temperature zones.

Dairy & Beverage Plants

Touchless hand disinfection prevents hand-borne microbes from entering processing lines. Furthermore, it maintains hygiene during milk, juice, and bottled-product handling.

Bakery & Dry Food Production

Flour dust and micro-particles can easily transfer into clean zones. However, the PBW-23 reduces this risk significantly, supporting strict GMP hygiene standards.

Cold Rooms & Low-Temperature Areas

Its stainless steel construction and stable sensors maintain functionality in chilled or humid environments. Meanwhile, it operates reliably in high-traffic zones.

Installation Guide for PBW-23 Hygiene Station

To achieve optimal performance:

Install the unit at main personnel entrances before cleanrooms or production zones.

Next, connect water, drainage, and electrical power according to the onsite layout.

Keep sanitizer and disinfectant tanks accessible for easy refilling.

Then, configure turnstile logic: hand & boot sanitation → turnstile unlock.

Finally, adjust boot brush rotation speed and disinfectant dosing as needed.

PBW-23 Hygiene Station Case Studie

Case 1 – Poultry Factory, Malaysia

15 units installed at main entrances. Consequently, personnel contamination incidents dropped by 48%. Moreover, performance remained stable in wet and humid zones.

Case 2 – Seafood Processing, Chile

Workers’ shoe soles and hands disinfected automatically. As a result, hygiene compliance improved significantly, with smooth integration into existing access control systems.

Case 3 – Dairy Plant, UAE

Turnstile ensures 100% hand and shoe sanitation. Ultimately, the plant passed HACCP audits with zero non-conformities, while maintenance remained minimal.

To achieve optimal performance, install the Hygiene Station PBW‑23 at main entry points before cleanrooms.

PBW-23 Hygiene Station FAQ

Q1: Does the PBW-23 wash hands?

No. Instead, it provides touchless hand disinfection only.

Q2: Can the boot brushes operate in wet areas?

Yes. They are designed for wet, humid, and cold environments.

Q3: What sanitizer is compatible?

Liquid or alcohol-based sanitizer is recommended; gel is not advised.

Q4: Does the turnstile unlock before sanitation?

No. It unlocks only after hands and boots are sanitized.

Q5: How often should disinfectants be refilled?

Typically every 1–3 days; high-traffic areas may require more frequent refills.

Q6: Can RFID or access control be integrated?

Yes. The system supports scanners, card readers, and output signals to existing systems.

Q7: Is the machine easy to clean?

Yes. It supports high-pressure cleaning and features hygienic stainless steel construction.

Recommended Resources for PBW-23 Hygiene Station

These authoritative references help facilities maintain hygiene, comply with regulations, and strengthen audit readiness.

Get in Touch / Send Inquiry

If you’re interested in the PBW-23 Hygiene Station or need a full hygiene solution:

Email: wone@woneclean.com

WhatsApp: +86 180 2644 8617

Inquiry Form: Use the form below

Contact us to learn more about the Hygiene Station PBW‑23 and other hygiene solutions.